Understanding the Different Types of Heavy Vehicle Exhaust Components

Understanding the Different Types of Heavy Vehicle Exhaust Components

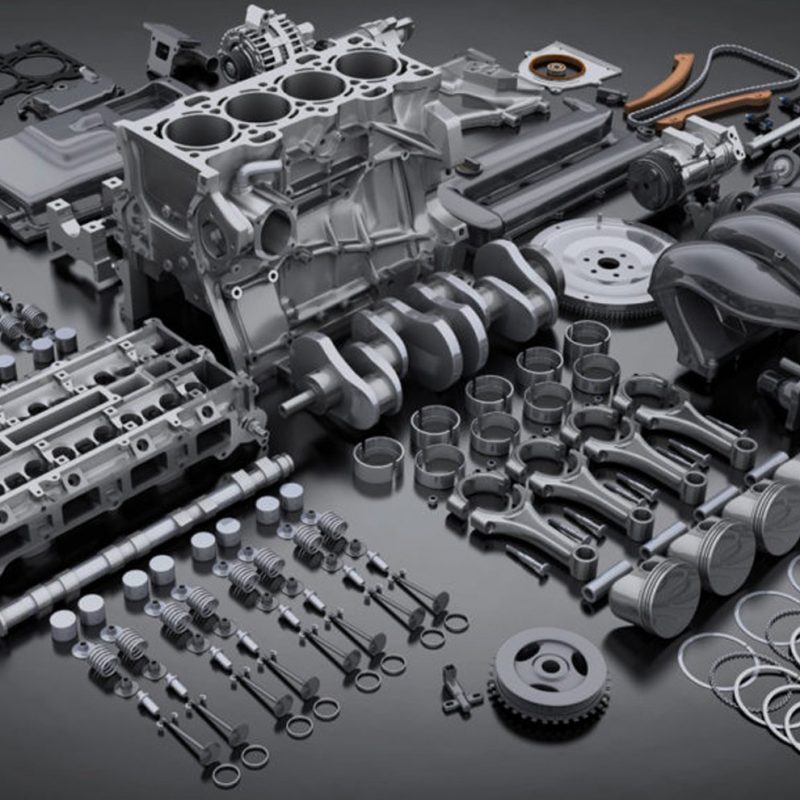

Heavy vehicles, such as trucks and buses, have complex exhaust systems that are designed to reduce emissions and improve the vehicle’s overall performance. Understanding the different types of heavy vehicle exhaust components is essential for proper maintenance and repair of these vehicles.

The first component of a heavy vehicle’s exhaust system is the exhaust manifold. The exhaust manifold is the point where the exhaust gases from the engine first enter the exhaust system. It is typically made of cast iron or stainless steel and is designed to collect the exhaust gases from the engine and direct them into the rest of the exhaust system.

The next component in the exhaust system is the catalytic converter. The catalytic converter is responsible for reducing harmful emissions from the exhaust gases. It is typically made of ceramic or metallic materials and contains a catalyst that chemically converts harmful pollutants, such as carbon monoxide and nitrogen oxides, into less harmful compounds.

The muffler is another important component of the exhaust system. The muffler is responsible for reducing the noise produced by the exhaust gases as they pass through the system. Mufflers are typically made of metal and are designed with internal chambers and baffles that absorb and dissipate the sound waves produced by the exhaust gases.

The exhaust pipe is another component of the exhaust system. The exhaust pipe is responsible for directing the exhaust gases from the muffler to the tailpipe and out of the vehicle. Exhaust pipes are typically made of steel or aluminum and are designed to withstand the high temperatures and pressures of the exhaust gases.

The tailpipe is the final component of the exhaust system. The tailpipe is responsible for directing the exhaust gases out of the vehicle and away from the occupants. Tailpipes are typically made of steel or aluminum and are designed to be durable and resistant to corrosion.

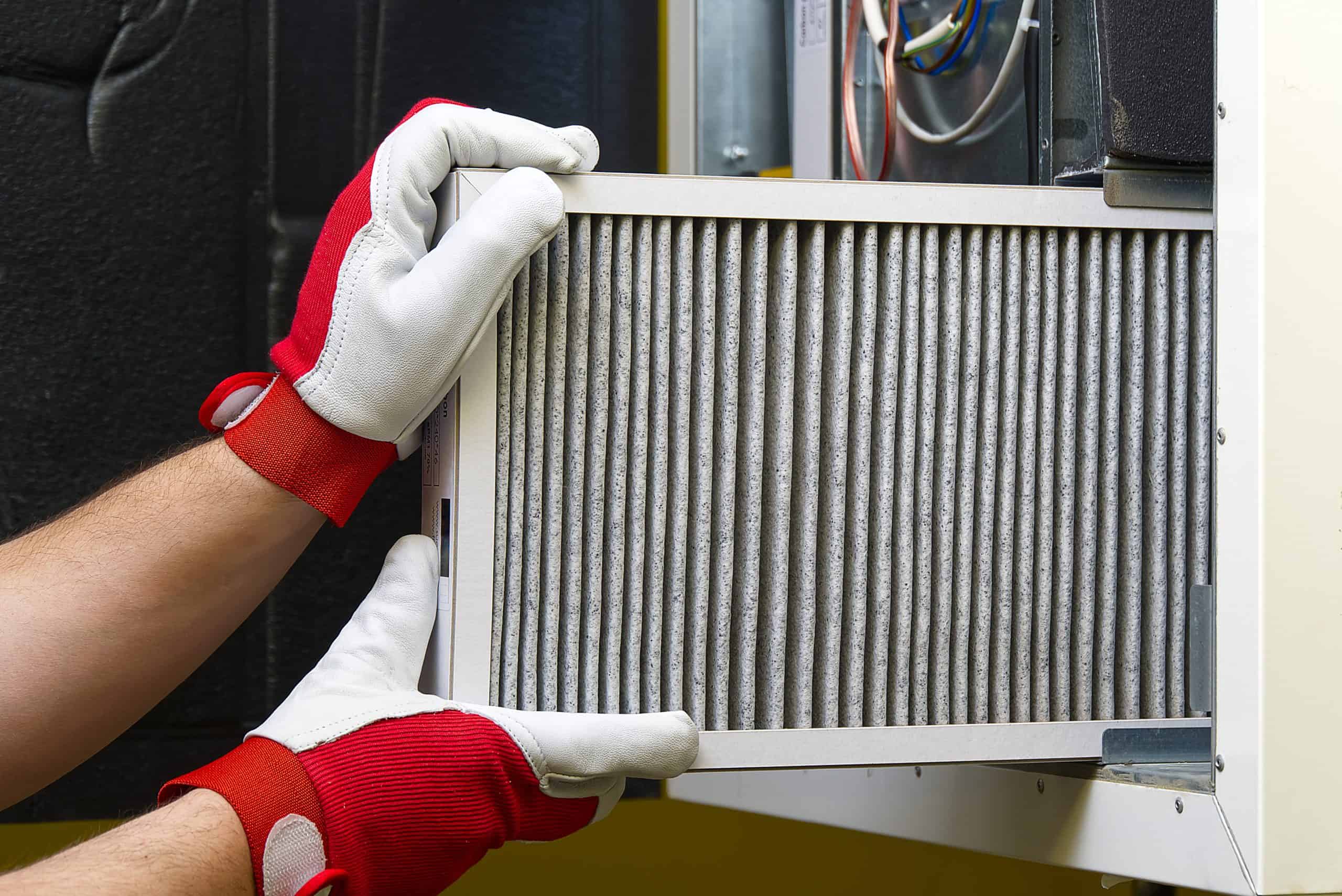

In addition to these components, heavy vehicles may also have other exhaust components, such as diesel particulate filters (DPF) and selective catalytic reduction (SCR) systems. DPF filters help to reduce particulate matter emissions from diesel engines, while SCR systems help to reduce nitrogen oxide emissions. These systems are important for meeting emissions regulations and maintaining the vehicle’s overall performance.

Proper maintenance of heavy vehicle exhaust components is essential for ensuring their proper function and longevity. This includes regular inspections, cleaning, and replacement of worn or damaged parts. It is important to follow the manufacturer’s recommended maintenance schedule for exhaust components, as well as to use high-quality components that meet or exceed the manufacturer’s specifications.

It is also important to be aware of any issues that may arise with the exhaust system, such as leaks or reduced performance. These issues can be caused by a variety of factors, including wear and tear, corrosion, and damage from road debris. Early detection and repair of these issues can help to prevent more serious problems from occurring and prolong the lifespan of the exhaust system.

In conclusion, heavy vehicles have complex exhaust systems that are designed to reduce emissions and improve the vehicle’s overall performance. Understanding the different types of heavy vehicle exhaust components is essential for proper maintenance and repair of these vehicles. Proper maintenance of exhaust components, including regular inspections, cleaning, and replacement of worn or damaged parts, is essential for ensuring their proper function and longevity. It is also important to be aware of any issues that may arise with the exhaust system and address them in a timely manner.