The Role of Spare Parts in Supply Chain Management

The Role of Spare Parts in Supply Chain Management

I. Introduction

Spare parts play a critical role in supply chain management, as they ensure that equipment and machinery continue to operate smoothly and efficiently. In many industries, such as manufacturing, transportation, and logistics, the availability of spare parts is essential for maintaining productivity and minimizing downtime. In addition, spare parts can also be used as a source of revenue, as they are often sold separately from the main product.

In this blog, we will explore the different aspects of spare parts supply chain management, including understanding the unique challenges and considerations associated with managing spare parts, best practices for forecasting and inventory management, and case studies of companies effectively managing their spare parts supply chain. We will also discuss future trends and developments in spare parts supply chain management and provide actionable steps for readers to improve their own spare parts management practices.

II. Understanding the Spare Parts Supply Chain

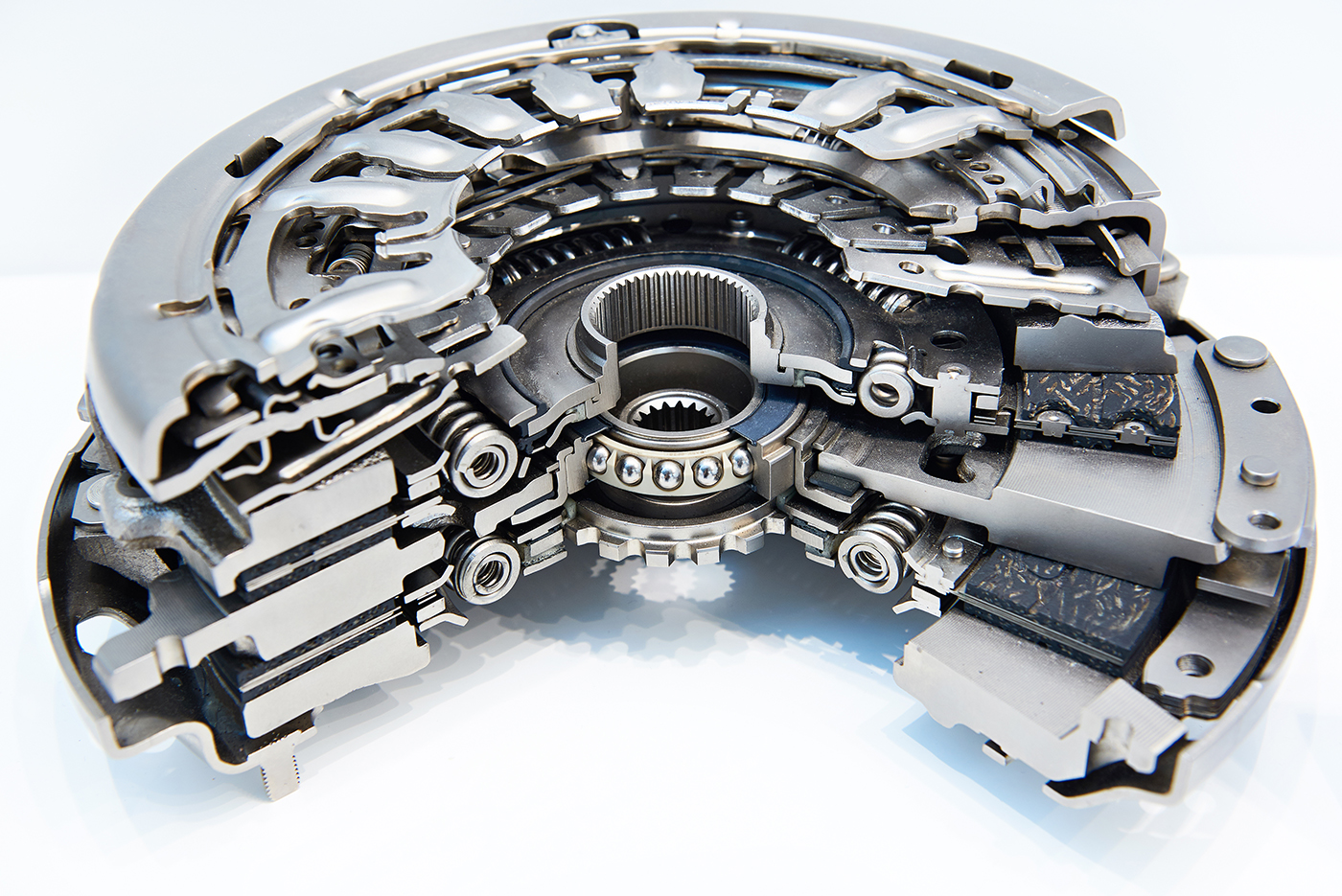

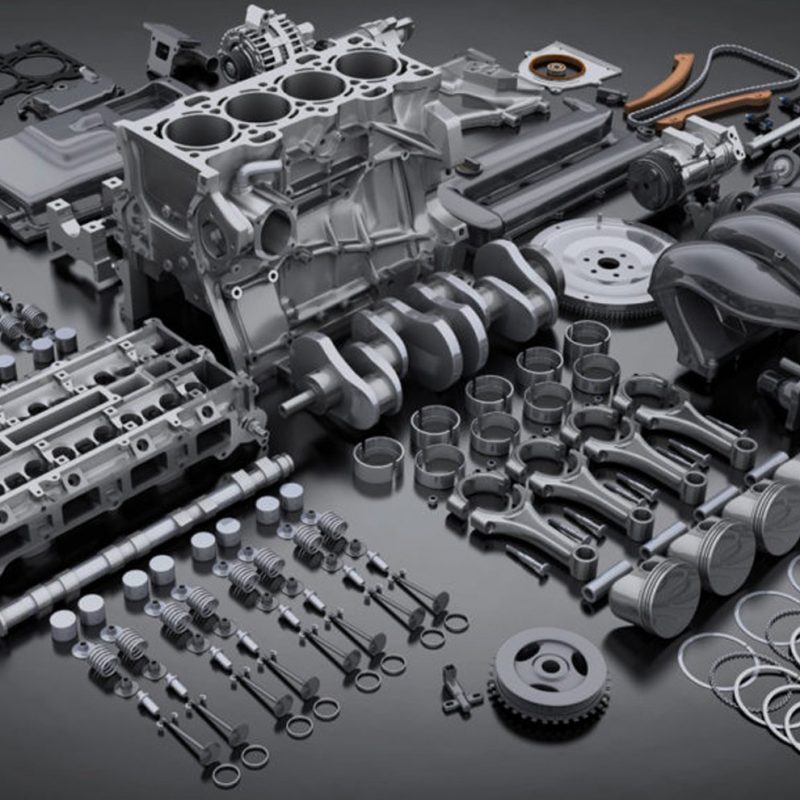

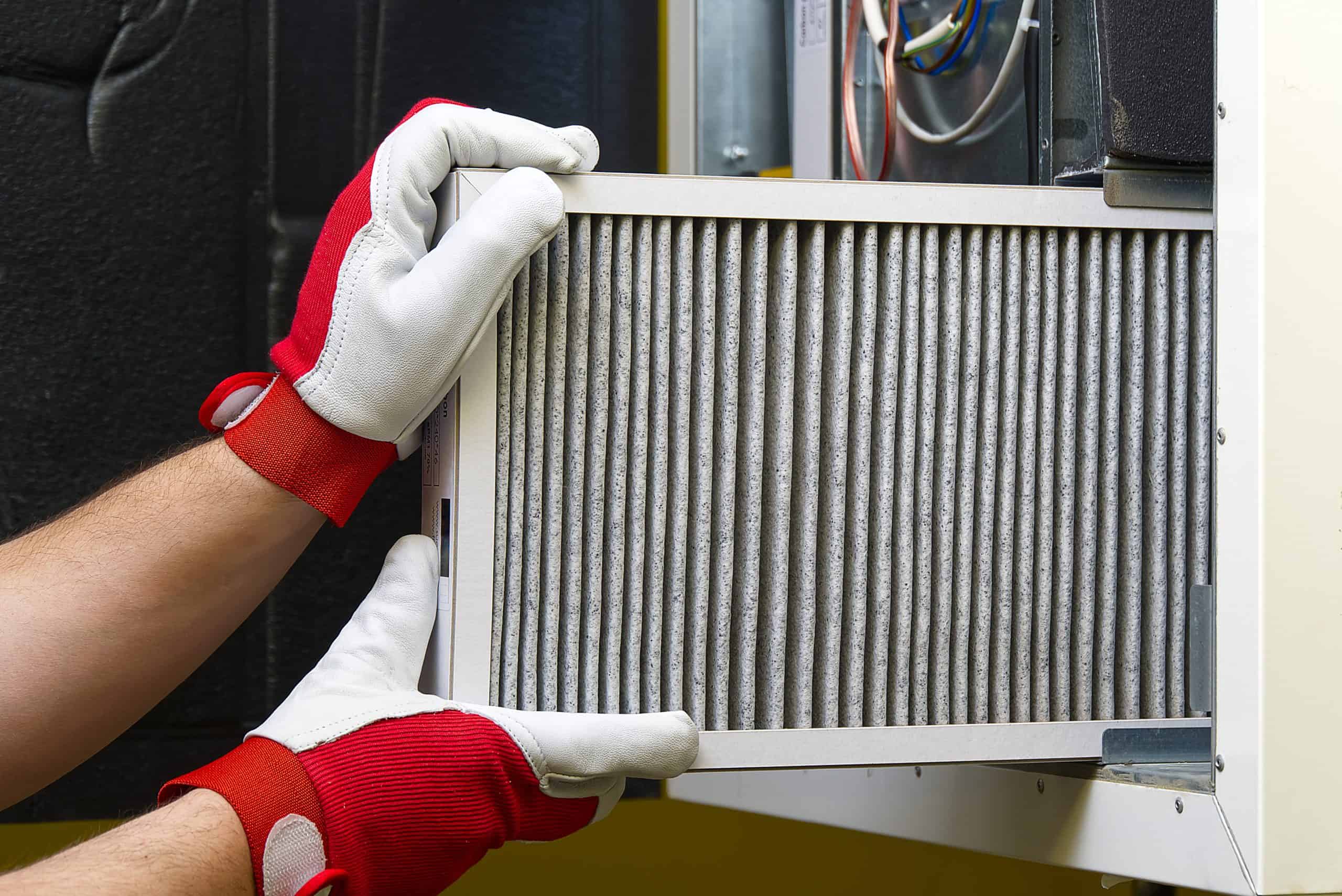

Spare parts can be categorized into two main types: consumable and durable. Consumable spare parts, such as lubricants and filters, have a limited lifespan and need to be regularly replaced. Durable spare parts, on the other hand, such as gears and bearings, have a longer lifespan and are only replaced when they fail or wear out.

Managing the spare parts supply chain is a complex task that requires a thorough understanding of the different types of spare parts, their lifecycle, and the specific needs of the industry. Some of the unique challenges and considerations associated with managing spare parts include:

- Forecasting and inventory management: predicting the demand for spare parts and ensuring that the right parts are available when needed is a crucial aspect of spare parts management.

- Lead times and delivery performance: spare parts may be sourced from a variety of suppliers and manufacturers, which can lead to long lead times and delivery delays.

- Data and technology: the use of data and technology can play a key role in managing spare parts, from forecasting demand to automating inventory management.

- Cost management: spare parts can be expensive, and managing costs is an important consideration in the spare parts supply chain.

These unique challenges and considerations require specific strategies and best practices to be adopted in order to effectively manage the spare parts supply chain. In the next section, we will discuss some of the best practices that can be implemented to improve spare parts management.

III. Best Practices for Managing Spare Parts

Effective management of spare parts requires a combination of strategies and best practices to ensure the right parts are available when needed and costs are kept under control. Some of the best practices for managing spare parts include:

- Forecasting and inventory management: Developing accurate demand forecasts and implementing inventory management strategies can help ensure that spare parts are available when needed while also reducing excess inventory. Techniques such as statistical forecasting and inventory optimization can be useful in this regard.

- Reducing lead times and improving delivery performance: Long lead times and delivery delays can have a significant impact on operations and productivity. To reduce lead times and improve delivery performance, companies can implement techniques such as supplier consolidation, vendor-managed inventory, and electronic data interchange.

- The importance of data and technology: Data and technology play a crucial role in managing spare parts. By using data and technology, companies can improve forecasting, optimize inventory levels, and automate many of the processes involved in spare parts management. Techniques such as data analytics, artificial intelligence, and the Internet of Things can be used to improve spare parts management.

- Cost management: Managing spare parts costs is a critical aspect of spare parts management. Cost reduction strategies, such as negotiating better prices with suppliers, can help to reduce costs.

By implementing these best practices and utilizing the appropriate technology, companies can improve the efficiency and effectiveness of their spare parts management, ultimately leading to cost savings and increased productivity.

IV. Case Studies and Examples

Understanding how other companies have successfully managed their spare parts supply chain can provide valuable insights and inspiration for your own operations. Here are a few real-world examples of companies that have effectively managed their spare parts supply chain:

- John Deere: John Deere, a leading manufacturer of agriculture and construction equipment, implemented a spare parts forecasting and inventory management system that utilizes data analytics and artificial intelligence. By accurately forecasting demand and optimizing inventory levels, John Deere was able to improve spare parts availability and reduce inventory costs.

- Boeing: Boeing, a leading aerospace manufacturer, has implemented a spare parts management system that utilizes RFID technology to track inventory and improve delivery performance. By using RFID, Boeing was able to significantly reduce lead times and improve delivery performance.

- GE Healthcare: GE Healthcare, a medical equipment manufacturer, developed a spare parts management system that utilizes data analytics and the Internet of Things to predict when spare parts will be needed and automatically order them. This system has helped GE Healthcare to improve spare parts availability and reduce inventory costs.

These case studies demonstrate the importance of implementing effective forecasting and inventory management strategies, as well as utilizing data and technology to improve spare parts management. By analyzing the strategies and best practices used by these companies, other organizations can learn how to improve their own spare parts management and gain similar benefits.