The Role of Spare Parts in Predictive Maintenance Strategies

The Role of Spare Parts in Predictive Maintenance Strategies

I. Introduction

A. Explanation of the importance of spare parts in predictive maintenance

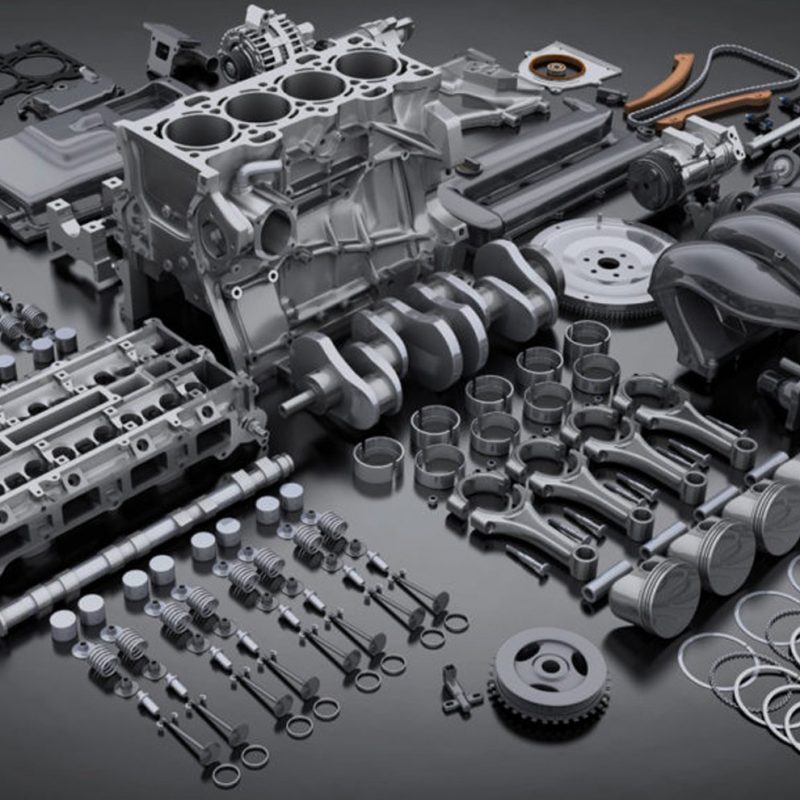

Spare parts play a critical role in the implementation of predictive maintenance strategies. Predictive maintenance relies on the ability to accurately predict when equipment will fail, so that repairs or replacements can be scheduled in advance. This helps to minimize downtime and prolong the lifespan of equipment. Spare parts are essential for this process because they allow for quick and efficient repairs or replacements when equipment does fail. Without an adequate supply of spare parts, a predictive maintenance strategy can’t be effectively executed.

B. Overview of the purpose of the blog

The purpose of this blog is to explore the role of spare parts in predictive maintenance strategies. We will discuss the importance of spare parts inventory management, how spare parts are used in predictive maintenance, and provide tips for implementing spare parts in your own predictive maintenance strategy. This blog will provide valuable information for anyone looking to improve their equipment maintenance processes and minimize downtime.

II. What is Predictive Maintenance?

A. Explanation of the concept

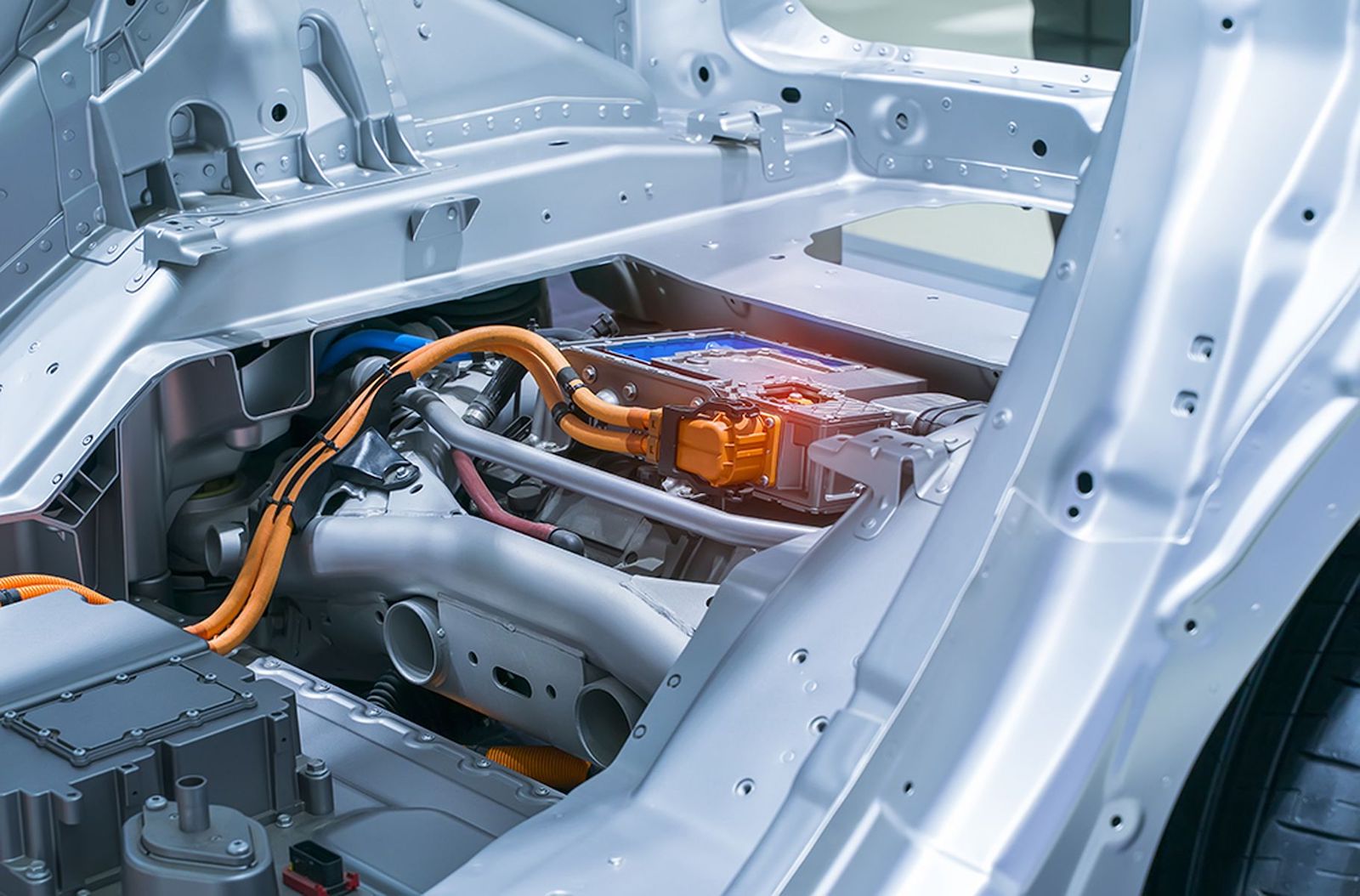

Predictive maintenance is a maintenance strategy that uses data and analytics to predict when equipment is likely to fail, so that repairs or replacements can be scheduled in advance. This is in contrast to reactive maintenance, where equipment is only fixed or replaced when it breaks down. Predictive maintenance relies on the collection of data on equipment performance, such as vibration levels, temperature, and oil analysis, to identify patterns that indicate an impending failure. This data is then analyzed to predict when equipment will require maintenance, allowing for proactive repairs and replacements.

B. Advantages of predictive maintenance over reactive maintenance

Predictive maintenance offers several advantages over reactive maintenance. By identifying potential problems before they occur, predictive maintenance can minimize downtime and prolong the lifespan of equipment. This can save companies significant money in the long run, as the cost of repairs is typically lower when problems are identified early. Predictive maintenance can also improve worker safety, as repairs can be scheduled during scheduled maintenance windows rather than in the event of an unexpected breakdown. Additionally, Predictive maintenance also allows for better resource allocation and can increase the overall efficiency of the maintenance process. With Predictive Maintenance, companies can know when to schedule maintenance, which minimize the need to have spare parts on-hand all the time, thus reducing inventory cost.

III. The Role of Spare Parts in Predictive Maintenance

A. Importance of spare parts inventory management

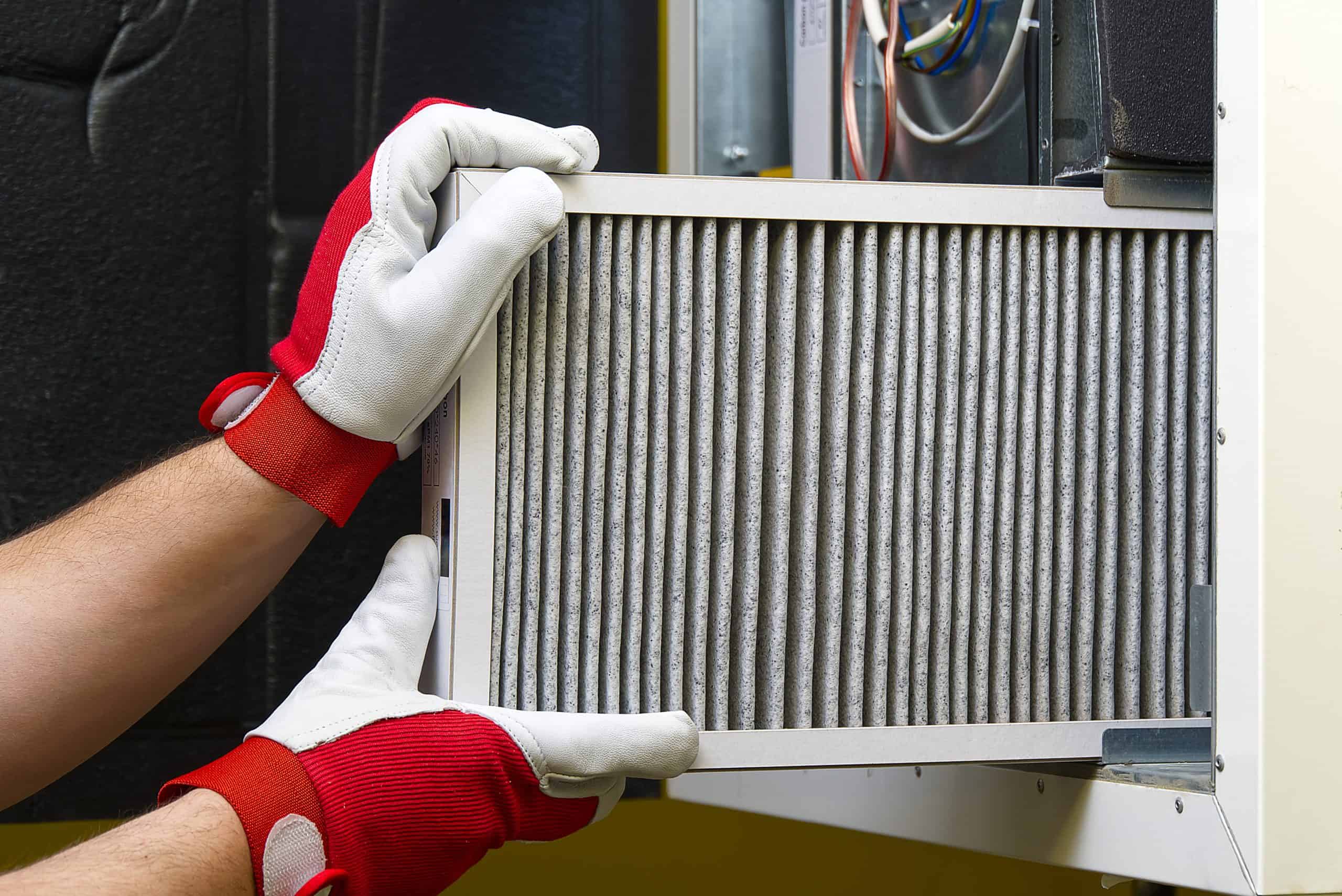

Spare parts inventory management is a crucial aspect of predictive maintenance. A well-managed inventory of spare parts allows for quick and efficient repairs or replacements when equipment fails. It also enables companies to minimize downtime and ensure that production is not interrupted. Without an adequate supply of spare parts, a predictive maintenance strategy can’t be effectively executed. To ensure an adequate supply of spare parts, companies need to have a clear understanding of their equipment and the parts that are likely to fail. This requires accurate inventory tracking and forecasting, as well as careful planning to ensure that spare parts are readily available when needed.

B. How spare parts are used in predictive maintenance

Spare parts are used in predictive maintenance to repair or replace equipment when it is predicted to fail. This can include parts such as bearings, gears, and motors. By identifying potential problems before they occur, predictive maintenance allows companies to schedule repairs or replacements during scheduled maintenance windows rather than in the event of an unexpected breakdown. This can minimize downtime and prolong the lifespan of equipment. Additionally, predictive maintenance can also help companies to optimize their spare parts inventory, by allowing them to plan their inventory based on the predicted failure rate of the equipment.

C. Case studies or examples of companies that have successfully implemented spare parts in predictive maintenance

Many companies have successfully implemented spare parts in their predictive maintenance strategies. For example, a manufacturing company that specializes in producing a wide range of consumer products, was able to reduce downtime by 50% by using predictive maintenance and implementing a comprehensive spare parts inventory management system. Another example is a large oil and gas company that was able to increase equipment lifespan by 20% and reduce maintenance costs by 15% by implementing predictive maintenance and optimizing their spare parts inventory. These case studies demonstrate the potential benefits of implementing spare parts in predictive maintenance strategies, including increased equipment lifespan, reduced downtime, and decreased maintenance costs.

IV. How to Implement Spare Parts in Predictive Maintenance

A. Steps to take to implement spare parts in predictive maintenance

Implementing spare parts in predictive maintenance can seem daunting, but it can be broken down into several key steps:

1. Understand your equipment: Understand the equipment you use, including the parts that are most likely to fail. This will help you to identify the spare parts that you need to keep on hand.

2. Create an inventory management plan: Develop a plan for managing your spare parts inventory. This should include forecasting, tracking, and reordering spare parts as needed.

3. Implement predictive maintenance: Implement predictive maintenance software or tools to help you predict when equipment will fail.

4. Schedule maintenance: Schedule maintenance during scheduled maintenance windows, rather than in the event of an unexpected breakdown.

5. Optimize inventory: Use the data from your predictive maintenance system to optimize your spare parts inventory, by identifying parts that are not used frequently or are not needed.

B. Tips for successful implementation

– Start small: Implementing spare parts in predictive maintenance can be a big undertaking, so it’s important to start small. Begin by selecting a few key pieces of equipment to focus on, and then expand from there.

– Communicate with your team: Make sure everyone on your team is aware of the changes you’re making and the benefits they will bring.

– Keep it simple: Keep your inventory management system simple and easy to use. This will make it easier for your team to use and will reduce the chance of errors.

– Continuously monitor and adjust: Continuously monitor the performance of your predictive maintenance system and make adjustments as needed.

C. Common challenges and how to overcome them

– Lack of data: One of the most common challenges when implementing predictive maintenance is a lack of data. If you don’t have enough data on your equipment, it can be difficult to predict when it will fail. To overcome this, start collecting data as soon as possible and invest in tools that can help you collect and analyze data.

– Limited budget: Another common challenge is limited budget. Implementing predictive maintenance and spare parts inventory management can be costly. To overcome this, start small and focus on the most critical equipment.

– Resistant to change: Some employees may be resistant to change, especially if they are used to traditional, reactive maintenance. To overcome this, communicate the benefits of predictive maintenance and spare parts inventory management, and provide training to help employees understand the new system.

V. Conclusion

A. Summary of the importance of spare parts in predictive maintenance

In conclusion, spare parts play a critical role in the implementation of predictive maintenance strategies. Predictive maintenance relies on the ability to accurately predict when equipment will fail, so that repairs or replacements can be scheduled in advance. Spare parts are essential for this process because they allow for quick and efficient repairs or replacements when equipment does fail. Without an adequate supply of spare parts, a predictive maintenance strategy can’t be effectively executed. By implementing spare parts in predictive maintenance strategies, companies can minimize downtime, prolong the lifespan of equipment, and reduce maintenance costs.

B. Call to action for companies to consider implementing spare parts in their predictive maintenance strategies.

If you’re looking to improve your equipment maintenance processes and minimize downtime, we strongly recommend considering implementing spare parts in your predictive maintenance strategy. By doing so, you’ll be able to take advantage of the many benefits that predictive maintenance offers, including increased equipment lifespan, reduced downtime, and decreased maintenance costs. It’s not always easy, but with the right planning, communication, and tools, it can be done. So, take the first step today and start exploring how you can incorporate spare parts into your predictive maintenance strategy.