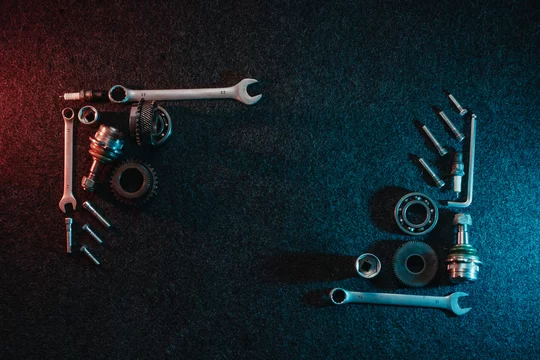

The Importance of Maintaining a Well-Stocked Spare Parts Inventory

The Importance of Maintaining a Well-Stocked Spare Parts Inventory

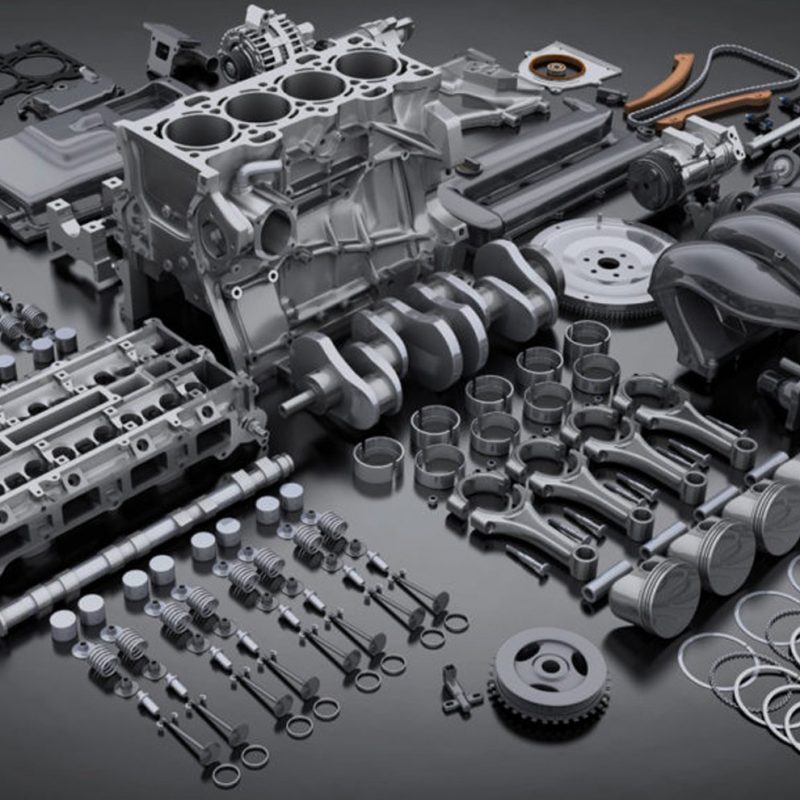

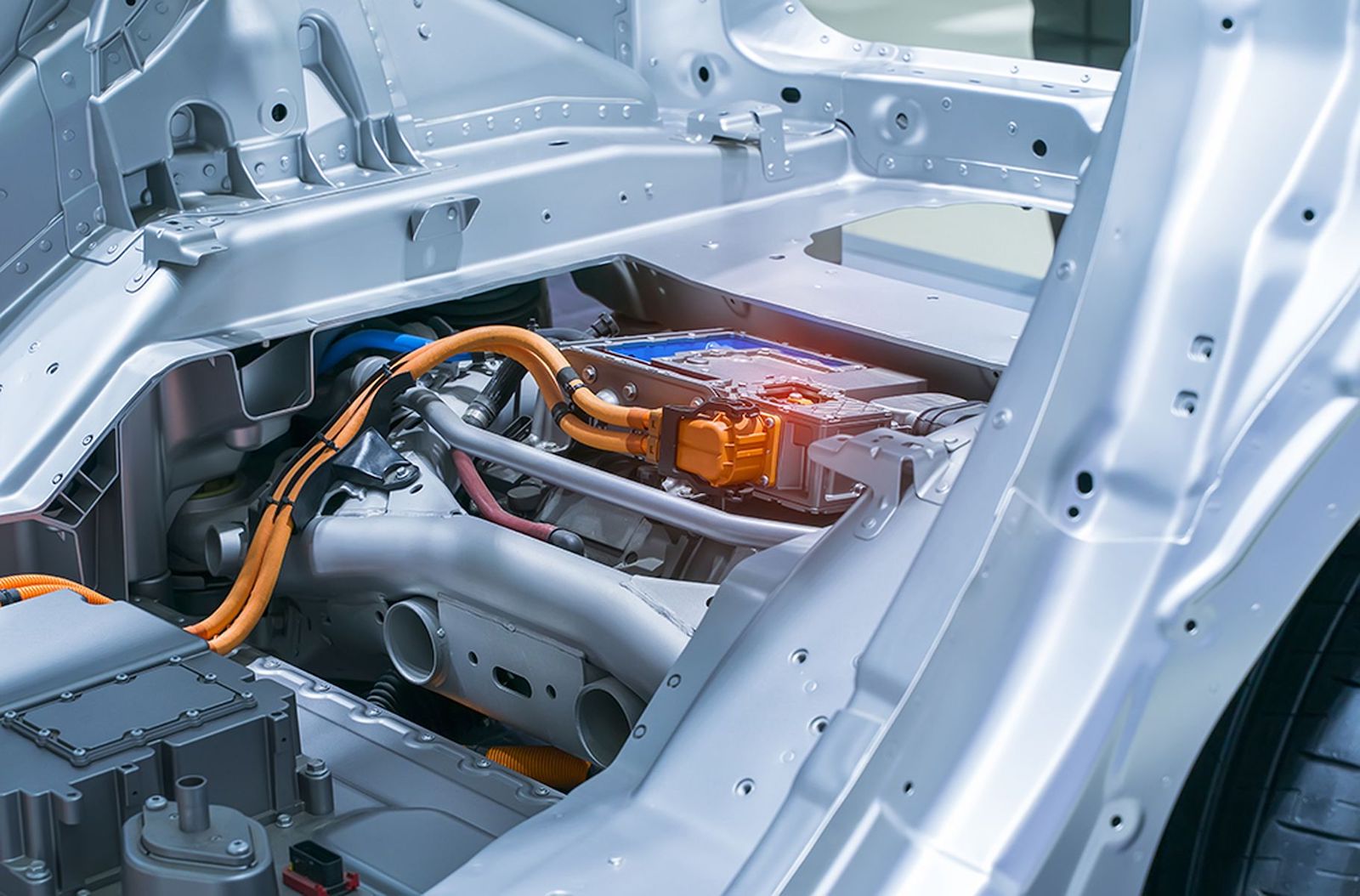

Maintaining a well-stocked spare parts inventory is essential for any business that manufactures products or provides services. Having a well-stocked inventory of spare parts helps to reduce production delays, maximize efficiency, and save costs. Without a well-stocked inventory of spare parts, businesses may have to order and rush-deliver spare parts, which can incur additional costs. A lack of spare parts can also lead to production delays and lost revenue.

On the other hand, having a well-stocked inventory of spare parts can lead to cost savings and increased efficiency. It can also lead to decreased downtime and increased productivity. In order to maintain a well-stocked spare parts inventory, businesses should employ forecasting and inventory management techniques. It is also important to identify and prioritize the most important spare parts to keep in stock.

In conclusion, maintaining a well-stocked spare parts inventory is essential for any business that manufactures products or provides services. It can help to reduce production delays, maximize efficiency, and save costs. Businesses should employ forecasting and inventory management techniques and identify and prioritize the most important spare parts to keep in stock.

In this introduction, let’s discuss the importance of maintaining a well-stocked spare parts inventory. Having a well-stocked inventory of spare parts is essential for any business that manufactures products or provides services. It helps to reduce production delays, maximize efficiency, and save costs. Without a well-stocked inventory of spare parts, businesses may have to order and rush-deliver spare parts, which can incur additional costs. A lack of spare parts can also lead to production delays and lost revenue.

In this section, let’s discuss the financial benefits of maintaining a well-stocked spare parts inventory. Having a well-stocked inventory of spare parts can lead to cost savings and increased efficiency. For example, when spare parts are readily available, businesses can save on rush-delivery costs and replacement parts costs. Additionally, having a well-stocked spare parts inventory can lead to decreased downtime and increased productivity. For instance, if a machine needs to be repaired, the repair time can be significantly reduced if the spare parts are readily available. This can help to reduce downtime and increase productivity.

II. The Costs of Not Maintaining a Well-Stocked Spare Parts Inventory

One of the main costs of not maintaining a well-stocked spare parts inventory is the constant need to order and rush-deliver spare parts. This can lead to increased expenses, such as rush shipping fees and expedited processing costs. Additionally, when spare parts are not readily available, production delays can occur, leading to lost revenue and missed deadlines.

For example, imagine a manufacturing facility that produces a high-demand product. If a key piece of equipment breaks down, and the necessary spare part is not readily available, production will come to a halt until the part can be obtained. This delay can result in missed delivery dates and loss of customers.

Another example could be a facility that operates with a 24/7 schedule. An unexpected breakdown and lack of spare parts can lead to costly downtime, and overtime pay for employees who are working to get the equipment back up and running. Not only that but it can also lead to a decrease in productivity, which can have a ripple effect on the entire supply chain.

It is clear that not maintaining a well-stocked spare parts inventory can have significant financial consequences for a business. However, by proactively managing and maintaining a well-stocked inventory, these costs can be minimized and avoided.

III. The Benefits of Maintaining a Well-Stocked Spare Parts Inventory

Maintaining a well-stocked spare parts inventory can provide a number of financial benefits for a business. One of the main benefits is cost savings. By having a well-stocked inventory, businesses can avoid the expensive costs associated with rush ordering and expedited shipping. This can result in significant savings over time.

In addition to cost savings, a well-stocked spare parts inventory can also lead to increased efficiency. When spare parts are readily available, equipment downtime can be minimized, and production can continue without interruption. This can lead to increased productivity and faster delivery times for customers.

For example, imagine a facility that produces a high-demand product. By maintaining a well-stocked spare parts inventory, the facility can quickly and easily replace any broken or worn-out equipment, minimizing downtime and maximizing productivity. This can result in increased output and faster delivery times, which can ultimately lead to increased revenue and customer satisfaction.

Another example could be a facility that operates with a 24/7 schedule. Having a well-stocked spare parts inventory can ensure that maintenance and repairs can be made quickly and efficiently, minimizing downtime and maximizing productivity.

In summary, maintaining a well-stocked spare parts inventory can provide a number of financial benefits, including cost savings and increased efficiency. It can also lead to decreased downtime and increased productivity, ultimately resulting in increased revenue and customer satisfaction.

IV. How to Maintain a Well-Stocked Spare Parts Inventory

Maintaining a well-stocked spare parts inventory is crucial for the smooth operation of any business. To ensure that you always have the necessary spare parts on hand, it is important to implement best practices for forecasting and inventory management.

One of the key best practices for maintaining a well-stocked spare parts inventory is forecasting. This involves predicting future demand for spare parts based on historical data and current trends. By forecasting future demand, businesses can ensure that they have the necessary spare parts on hand, without overstocking and wasting resources.

Another important best practice is inventory management. This involves regularly monitoring and evaluating the spare parts inventory to ensure that it is accurate and up-to-date. This includes monitoring stock levels, identifying slow-moving or obsolete items, and making adjustments to the inventory as needed.

In addition to forecasting and inventory management, it is also important to identify and prioritize the most important spare parts to keep in stock. This includes identifying critical spare parts that are essential for the operation of key equipment or machinery, as well as common spare parts that are frequently used.

To identify and prioritize spare parts, businesses can use various techniques such as:

- Pareto analysis, which involves identifying the 20% of spare parts that account for 80% of usage

- ABC analysis, which involves classifying spare parts based on their importance and usage

- FMEA (Failure Modes and Effects Analysis), which involves identifying potential failure modes and their impact on the operation

By implementing these best practices, businesses can ensure that they always have the necessary spare parts on hand, minimizing downtime and maximizing productivity.

V. Conclusion

In conclusion, maintaining a well-stocked spare parts inventory is crucial for the smooth operation of any business. It can provide a number of financial benefits, including cost savings and increased efficiency, as well as decreased downtime and increased productivity. By implementing best practices for forecasting and inventory management, businesses can ensure that they always have the necessary spare parts on hand.

It is important for businesses to understand that not having a well-stocked spare parts inventory can result in significant financial consequences, such as production delays, lost revenue, and increased expenses. Therefore, it is crucial for businesses to take steps to improve their spare parts inventory management.

To improve spare parts inventory management, businesses can implement the following steps:

- Conduct a thorough inventory audit to identify slow-moving or obsolete items

- Forecast future demand for spare parts

- Identify and prioritize the most important spare parts to keep in stock

- Regularly monitor and evaluate the spare parts inventory

By taking these steps, businesses can ensure that they always have the necessary spare parts on hand, minimizing downtime and maximizing productivity. This can ultimately lead to increased revenue and customer satisfaction.