The Importance of Accurate Spare Parts Data in Supply Chain Management

The Importance of Accurate Spare Parts Data in Supply Chain Management

I. Introduction

Supply chain management is a critical aspect of any business, as it involves the coordination and management of all activities involved in the production, delivery, and distribution of a product or service. From sourcing raw materials to delivering the final product to the customer, the supply chain encompasses a wide range of activities that must be managed effectively to ensure the success of the business.

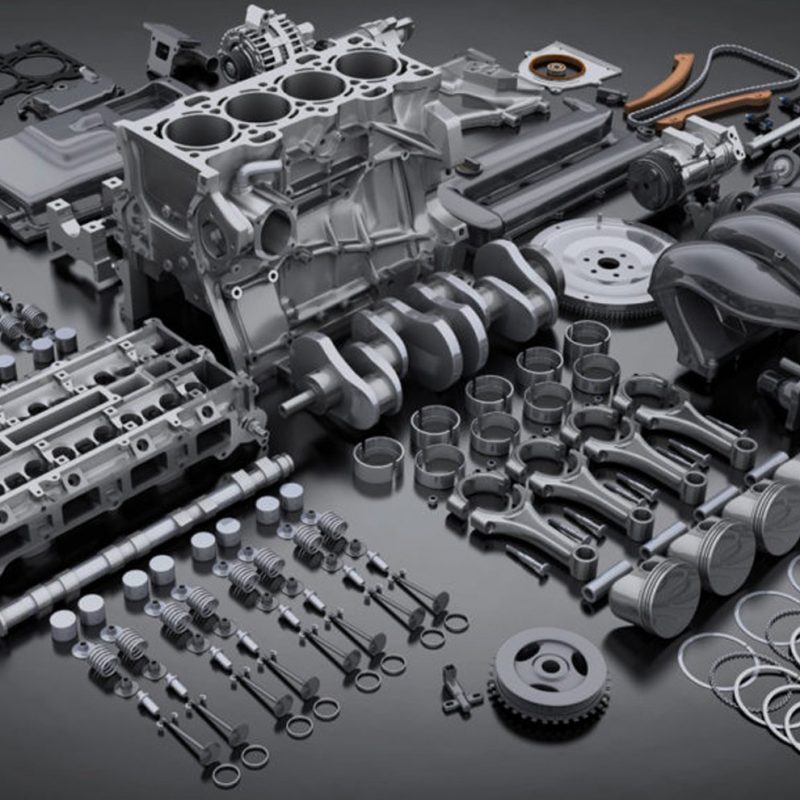

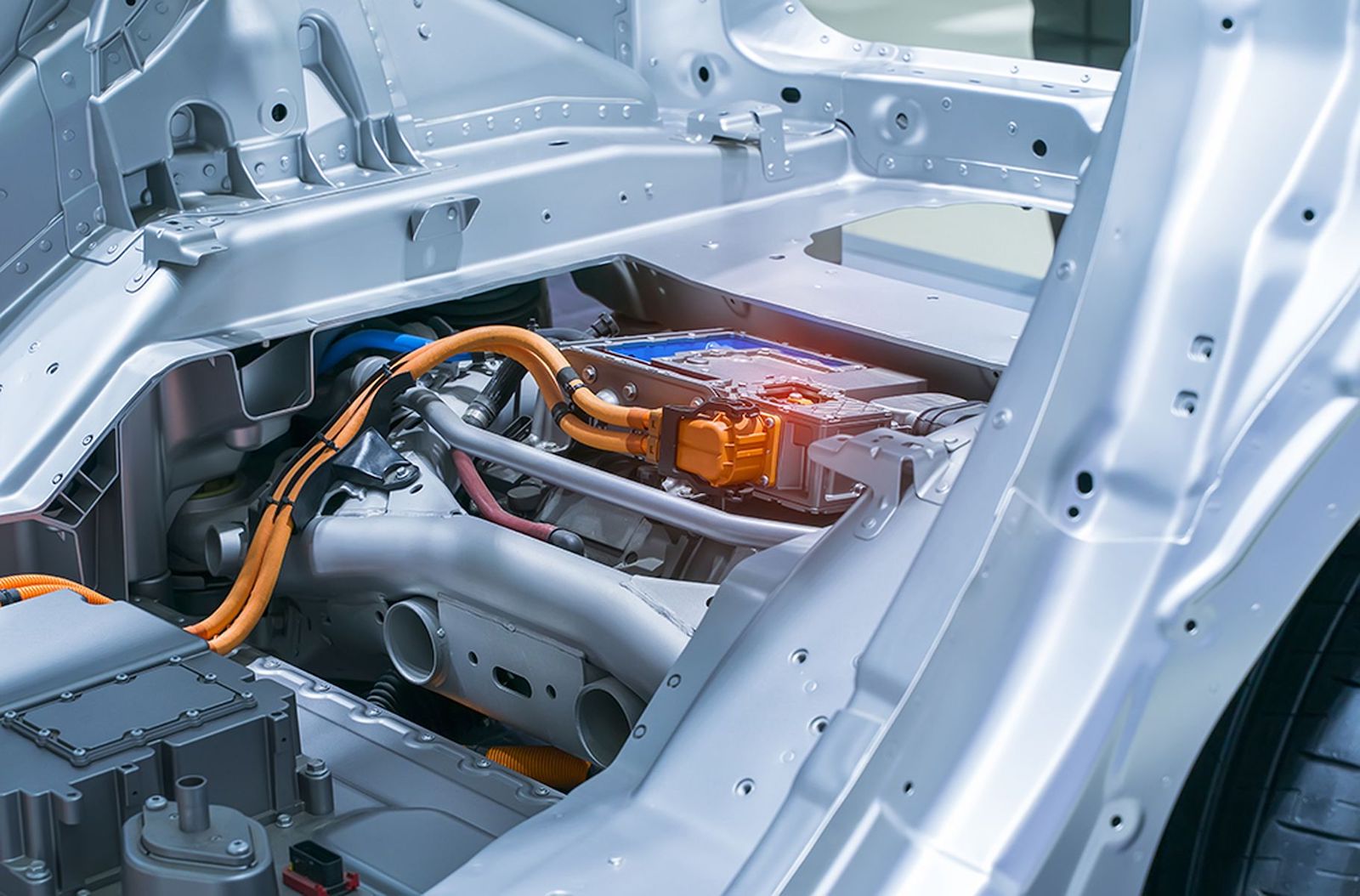

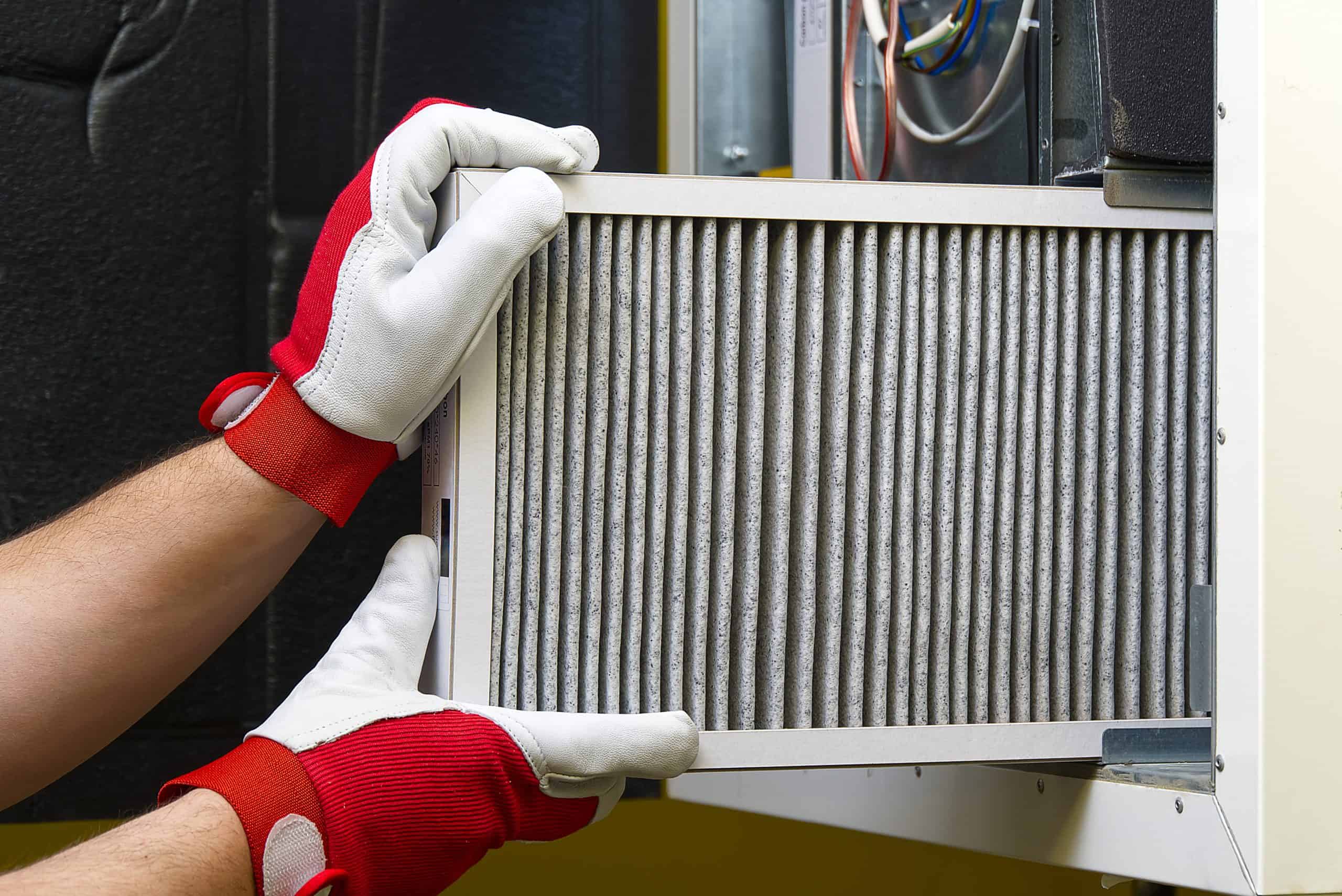

One important aspect of supply chain management is the management of spare parts data. Spare parts, also known as replacement parts or service parts, are critical components that are used to repair or maintain products. They are essential for ensuring that products are available and functioning correctly, and they can have a significant impact on the overall efficiency of the supply chain.

However, managing spare parts data can be a complex and challenging task. This is because spare parts data is often distributed across different systems and departments, and it can be difficult to ensure that it is accurate, up-to-date, and easily accessible to those who need it. Inaccurate or unreliable spare parts data can lead to inefficiencies and increased costs in supply chain management.

In this blog post, we will delve deeper into the importance of accurate spare parts data in supply chain management and discuss the challenges, benefits, and best practices for managing it effectively.

II. The challenges of managing spare parts data

Managing spare parts data can be a complex and challenging task for many organizations. One of the main challenges is the lack of standardization in spare parts data. Different departments, systems, and suppliers may use different data formats, codes, and descriptions, making it difficult to share, compare, and use the data effectively. This can lead to data silos, where different parts of the organization have access to different sets of spare parts data that may not be compatible with each other.

Another challenge is the lack of accuracy and completeness of spare parts data. This can happen due to human error, outdated information, or lack of data governance and control. Inaccurate or incomplete spare parts data can lead to incorrect inventory levels, delayed or incorrect shipments, and even production downtime.

In addition, managing spare parts data also requires significant investment in software, hardware, and human resources. Organizations may struggle to provide the necessary resources to ensure that spare parts data is accurate and up-to-date.

All these challenges can lead to inefficiencies and increased costs in supply chain management. These inefficiencies can result in higher inventory costs, delays in delivery, and increased downtime, which can ultimately impact customer satisfaction and the bottom line of the business.

III. The benefits of accurate spare parts data

Accurate spare parts data can bring many benefits to supply chain management. One of the main benefits is improved inventory management. With accurate spare parts data, organizations can better predict and manage their inventory levels, which can help to reduce overstocking and stockouts. This, in turn, can lead to cost savings on inventory carrying costs and improve customer satisfaction by ensuring that the right products are available at the right time.

Another benefit of accurate spare parts data is reduced downtime. With accurate spare parts data, organizations can quickly identify and locate the spare parts they need to repair or maintain their products, which can help to minimize downtime and increase productivity.

Accurate spare parts data can also improve the efficiency of supply chain operations. For example, with accurate spare parts data, organizations can better plan and schedule maintenance and repair activities, which can help to reduce lead times and improve delivery times. Additionally, accurate spare parts data can also facilitate the efficient and cost-effective sourcing of spare parts from suppliers.

Moreover, accurate spare parts data can also provide valuable insights that can help organizations to improve their product design and development. By keeping track of the spare parts used for repairs and maintenance, organizations can identify patterns and trends that can indicate opportunities for product improvements, which can help to reduce costs, increase customer satisfaction, and maintain a competitive edge.

In summary, accurate spare parts data can help organizations to improve inventory management, reduce downtime, increase efficiency, and make better decisions in supply chain management, which can ultimately lead to cost savings and increased revenue.

IV. Best practices for managing spare parts data

To effectively manage spare parts data, organizations should implement best practices that can help to ensure accuracy, reliability, and accessibility of the data. One of the most important best practices is implementing a central database for storing and managing spare parts data. This central database should be accessible to all relevant departments and stakeholders, and it should be regularly updated and maintained to ensure that the data is accurate and up-to-date.

Another best practice is standardizing the data. This can be done by implementing a common set of codes, descriptions, and data formats for spare parts data across the organization. This can help to ensure that the data is consistent and can be easily shared, compared, and used across different systems and departments.

To ensure data accuracy, data governance and control should be implemented. This can be done by establishing clear roles and responsibilities for data management and by implementing processes for data validation, verification, and updating.

It’s also important to consider the data security, implementing the necessary measures to prevent data breaches and unauthorized access to spare parts data.

Additionally, organizations can also consider investing in specialized software and tools for managing spare parts data, such as computerized maintenance management systems (CMMS) and enterprise resource planning (ERP) systems. These systems can help to automate and streamline the management of spare parts data, which can help to reduce errors and increase efficiency.

In summary, implementing a central database, standardizing data, implementing data governance and control, investing in specialized software and tools and ensuring data security are some of the best practices that can help organizations achieve accurate and reliable spare parts data. By following these best practices, organizations can ensure that their spare parts data is accurate, up-to-date, and easily accessible, which can help to improve supply chain efficiency and reduce costs.

V. Conclusion

In conclusion, accurate spare parts data is an essential aspect of supply chain management. It can help organizations to improve inventory management, reduce downtime, increase efficiency, and make better decisions. However, managing spare parts data can be a complex and challenging task. To effectively manage spare parts data, organizations should prioritize accurate spare parts data management by implementing best practices such as implementing a central database, standardizing data, implementing data governance and control, investing in specialized software and tools and ensuring data security.

By following these best practices, organizations can ensure that their spare parts data is accurate, up-to-date, and easily accessible, which can help to improve supply chain efficiency and reduce costs. With accurate spare parts data, organizations can make better decisions, increase productivity, and ultimately increase revenue. Therefore, it is important for organizations to invest in accurate spare parts data management to ensure the success of their supply chain operations.