Maximizing the Lifespan of Your Spare Parts through Proper Storage and Handling

Maximizing the Lifespan of Your Spare Parts through Proper Storage and Handling

I. Introduction

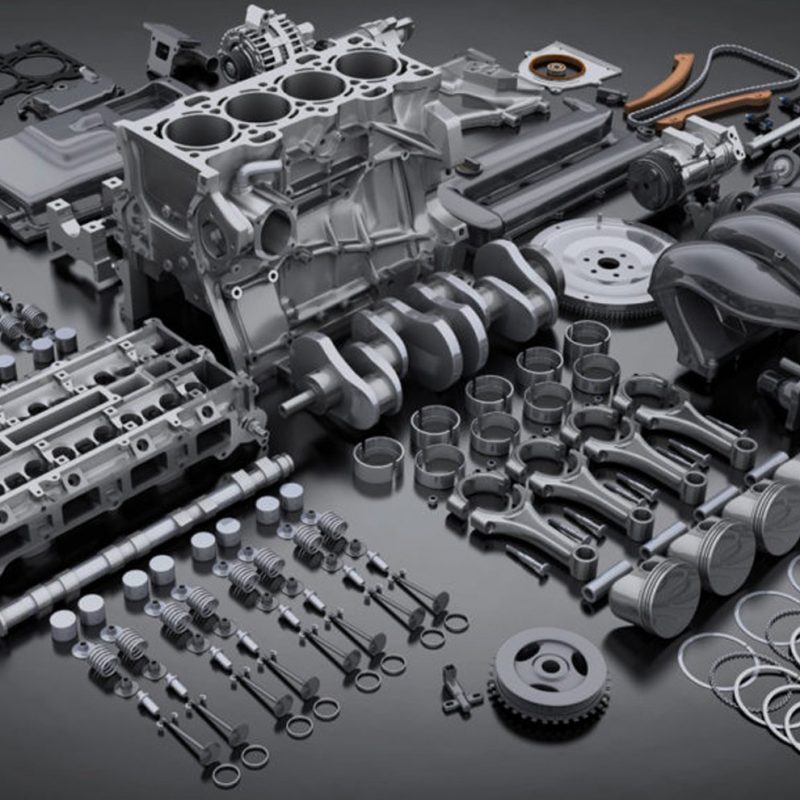

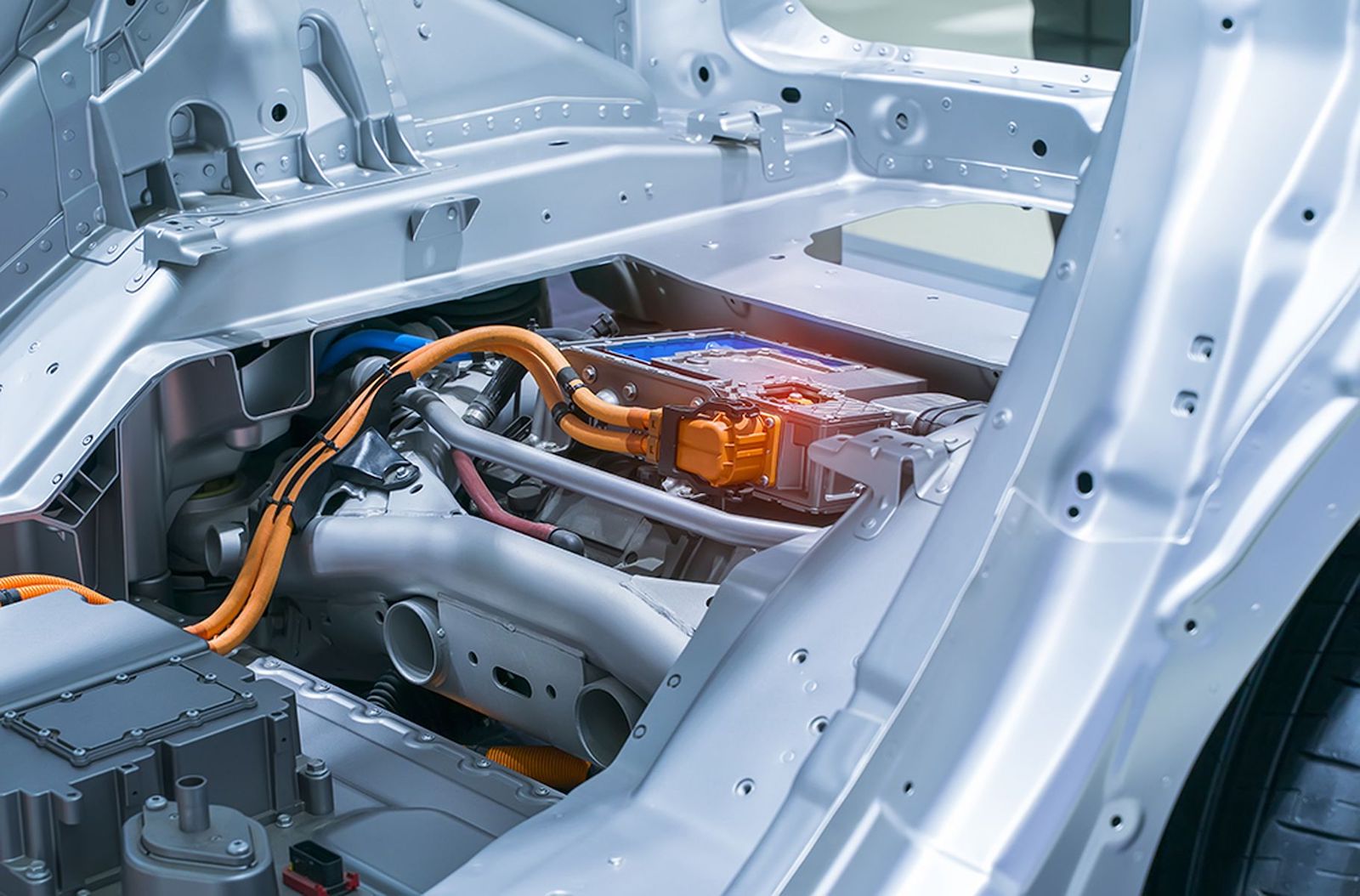

A. Explanation of the importance of spare parts in maintaining equipment and machinery

Spare parts are an essential component in keeping equipment and machinery running smoothly. They are the backup components that are used when the original parts fail or need to be replaced. Without spare parts, equipment downtime can be prolonged and costly, resulting in lost productivity and revenue.

B. Overview of the problem of spare parts not lasting as long as they should

Unfortunately, spare parts often do not last as long as they should. This can be due to a variety of reasons such as improper storage and handling, lack of maintenance, or even simply wear and tear. When spare parts fail prematurely, it can lead to unexpected downtime and additional costs for replacement parts. It is important to understand the root cause of the problem and to take steps to address it in order to maximize the lifespan of spare parts.

II. Proper Storage

A. Explanation of the proper storage conditions for spare parts

1. Temperature and humidity: Spare parts should be stored in a temperature-controlled environment, preferably between 60-70 °F and at a humidity level of 40-50%. Exposure to extreme temperatures and humidity can cause rust, corrosion, and other forms of damage to the spare parts.

2. Cleanliness and dust-free environment: Spare parts should be stored in a clean and dust-free environment. Dust and debris can cause damage to the spare parts over time, and can also make it difficult to identify the parts when they are needed.

3. Protection from physical damage: Spare parts should be stored in a way that protects them from physical damage, such as impacts or crushing. This may involve using protective packaging or storing the parts in a designated area away from heavy machinery.

B. Discussion of the importance of proper labeling and organization of spare parts

Proper labeling and organization of spare parts is crucial for easy identification and retrieval when needed. Clear labels with part numbers, descriptions, and location information can help to ensure that the correct part is selected and used. Additionally, organizing spare parts by type, size, or function can help to keep them properly stored and easily accessible.

III. Proper Handling

A. Explanation of the proper handling techniques for spare parts

1. Careful lifting and carrying: When handling spare parts, it is important to use proper lifting and carrying techniques to prevent damage. This may involve using lifting equipment or getting assistance from another person when moving heavy or bulky parts.

2. Avoiding unnecessary movement or handling: Spare parts should be handled as little as possible to minimize wear and tear. Avoid moving parts unless it is absolutely necessary and try to minimize the number of times they are handled.

3. Inspecting for damage before use: Before using a spare part, it is important to inspect it for any signs of damage or wear. This can help to identify any problems early on and prevent them from causing further damage to equipment or machinery.

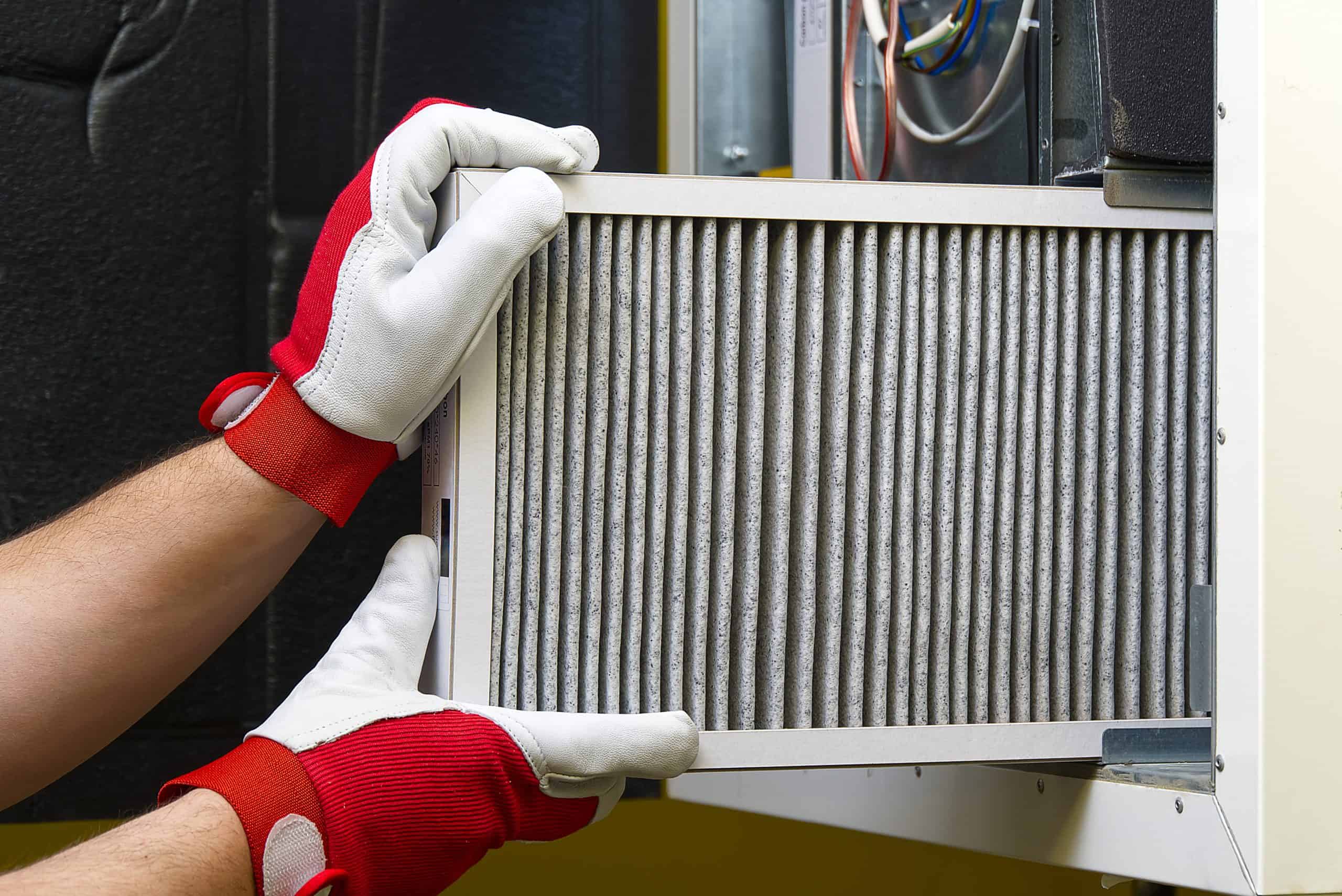

B. Discussion of the importance of proper maintenance and cleaning of spare parts

Proper maintenance and cleaning of spare parts is essential for maximizing their lifespan. This may include regular cleaning to remove dust and debris, lubrication to prevent rust and corrosion, and other forms of preventative maintenance. Additionally, it is important to keep track of the condition of spare parts over time and to replace them when they show signs of wear or damage.

IV. Conclusion

A. Summary of the importance of proper storage and handling for maximizing the lifespan of spare parts

Proper storage and handling of spare parts is essential for maximizing their lifespan and ensuring that equipment and machinery are running smoothly. Proper storage conditions, including temperature control, cleanliness, and protection from physical damage, can prevent rust, corrosion, and other forms of damage to spare parts. Proper handling techniques, including careful lifting, avoiding unnecessary movement, and inspecting for damage before use, can also help to extend the lifespan of spare parts.

B. Call to action for implementing proper storage and handling practices in the workplace

Implementing proper storage and handling practices in the workplace is vital to ensure the longevity of spare parts and to keep equipment and machinery running smoothly. This may involve creating a designated storage area, implementing proper labeling and organization, and providing training on proper handling techniques to employees. Additionally, regular inspection, maintenance, and cleaning of spare parts can also help to ensure their longevity. It is important for companies to make a commitment to proper storage and handling in order to minimize downtime and costs.