he Role of Standardization in Spare Parts Management

The Role of Standardization in Spare Parts Management

I. Introduction

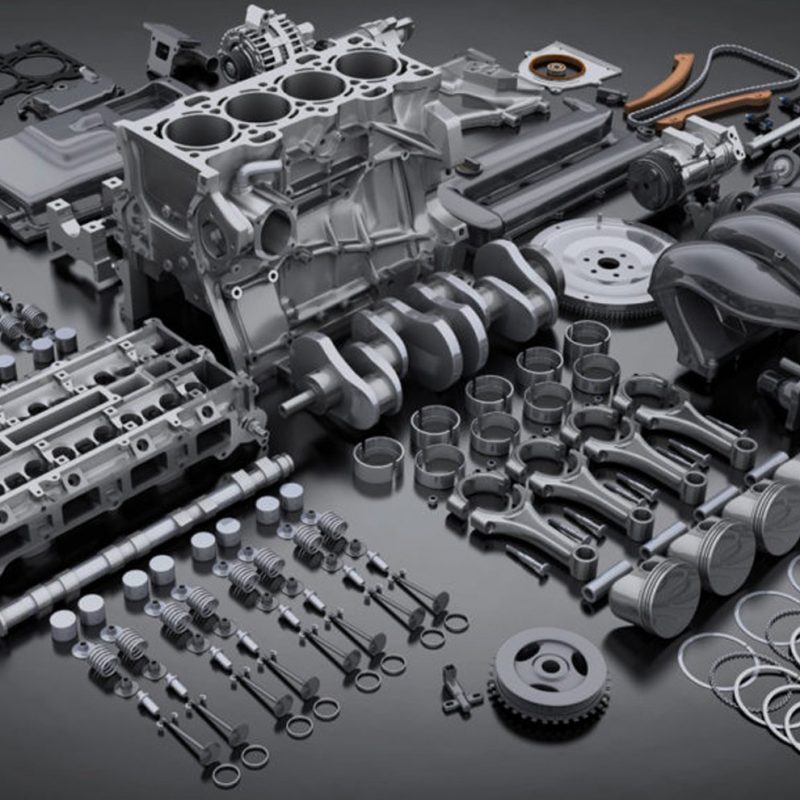

A. Explanation of spare parts management

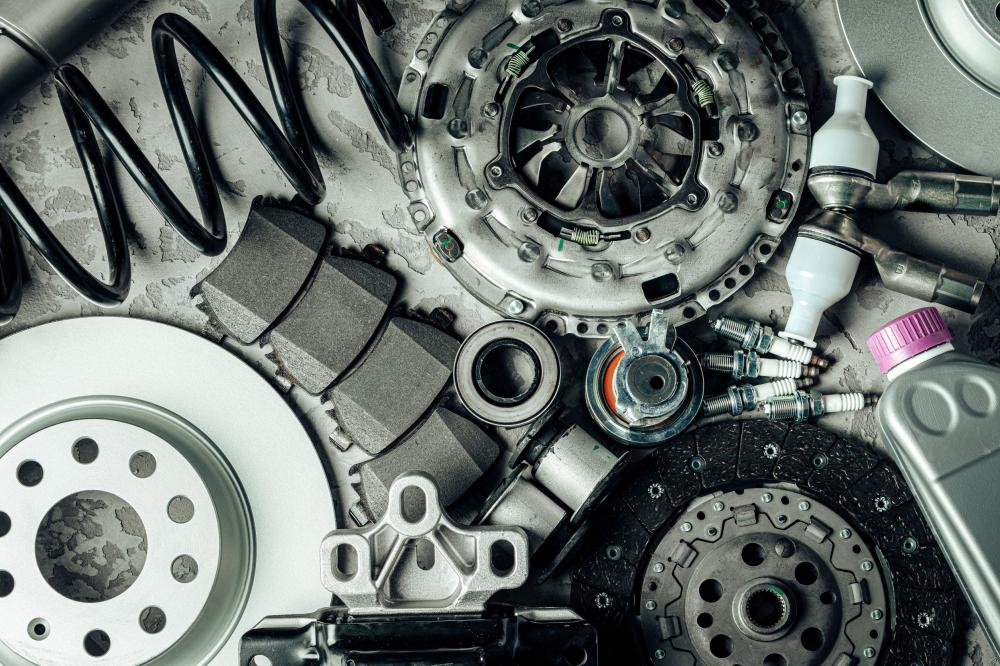

Spare parts management refers to the process of managing and organizing the spare parts used in various industries such as manufacturing, maintenance, and repair. It involves the identification, procurement, storage, and distribution of spare parts to ensure that they are available when needed to keep equipment and machines running smoothly.

B. Importance of standardization in spare parts management

Standardization is crucial in spare parts management as it helps to improve inventory control, reduce costs, increase efficiency, and improve customer satisfaction. With standardization, spare parts can be easily identified, procured, and tracked, which makes it easier to manage inventory and reduce waste. Additionally, standardization makes it easier to ensure that the right parts are being used in the right equipment, which helps to prevent downtime and prolong the life of equipment.

C. Purpose of the blog

The purpose of this blog is to explore the role of standardization in spare parts management, including the benefits it provides, the challenges it poses, and the solutions that can be employed to overcome them. We will also discuss the steps that can be taken to implement standardization in spare parts management, and provide an overview of the future outlook for this field.

II. Benefits of Standardization in Spare Parts Management

A. Improved inventory control

Standardization of spare parts helps to improve inventory control by making it easier to identify, track, and manage spare parts. With standardization, spare parts can be easily located, and inventory levels can be more accurately tracked, which helps to reduce the risk of stockouts and overstocking. Additionally, standardization makes it easier to identify obsolete parts and replace them with newer, more efficient ones, which helps to improve inventory turnover and reduce waste.

B. Reduced costs

Standardization of spare parts can help to reduce costs in several ways. By standardizing parts, it is possible to take advantage of economies of scale and purchase parts in bulk, which can lead to significant cost savings. Additionally, standardization makes it easier to track inventory and identify obsolete parts, which helps to reduce waste and lower the overall cost of spare parts management.

C. Increased efficiency

Standardization of spare parts can help to increase efficiency in several ways. By standardizing parts, it is possible to reduce the time and effort required to identify, procure, and track spare parts, which helps to improve overall efficiency. Additionally, standardization makes it easier to ensure that the right parts are being used in the right equipment, which helps to prevent downtime and prolong the life of equipment, which can lead to a more efficient operation overall.

D. Improved customer satisfaction

Standardization of spare parts can help to improve customer satisfaction by making it easier to identify and track parts, which can help to ensure that the right parts are delivered to customers quickly and efficiently. Additionally, standardization can help to improve the quality of spare parts, which can lead to fewer defects and less downtime for customers, which can lead to a better customer experience overall.

III. Implementing Standardization in Spare Parts Management

A. Identifying and standardizing parts

The first step in implementing standardization in spare parts management is to identify and standardize the parts that are used in your operation. This involves cataloging all of the spare parts that are used, including their make, model, and specifications. Once the parts have been identified, it is important to standardize them by selecting a single supplier for each part and specifying a standard part number. This helps to ensure that the right parts are being used in the right equipment and that they are easily identifiable and trackable.

B. Establishing a numbering system

Once the parts have been identified and standardized, the next step is to establish a numbering system. This involves assigning a unique number to each part and creating a numbering system that makes it easy to identify and track parts. This can be done by creating a parts catalog that includes the part number, description, and other relevant information for each part.

C. Creating a parts catalog

Creating a parts catalog is an essential step in implementing standardization in spare parts management. A parts catalog can be used to track inventory levels, identify obsolete parts, and manage the procurement of new parts. It should include detailed information about each part, including the part number, description, supplier, and pricing information. This information can be used to manage inventory levels and reduce waste.

D. Implementing a barcoding system

Implementing a barcoding system is another important step in implementing standardization in spare parts management. Barcoding allows parts to be easily identified and tracked, which helps to improve inventory control and reduce waste. Barcode labels can be placed on parts and scanned at various stages of the spare parts management process, including when parts are received, stored, and issued. This information can be used to track inventory levels and manage the procurement of new parts.

IV. Challenges and Solutions in Standardization

A. Resistance to change

One of the biggest challenges in implementing standardization in spare parts management is resistance to change. Some employees may be resistant to new processes and procedures and may be unwilling to change their current way of working. This can be overcome by involving employees in the process of standardization and providing training on the new procedures. Additionally, it is important to clearly communicate the benefits of standardization and how it will improve the overall operation.

B. Maintaining standardization

Maintaining standardization can also be a challenge, as new parts and equipment may be added, and suppliers may change over time. It is important to regularly review and update the parts catalog to ensure that it remains accurate and up-to-date. Additionally, it is important to establish procedures for managing exceptions and non-standard parts, and to ensure that all employees are aware of these procedures.

C. Managing exceptions

Managing exceptions is another challenge in standardization, as there may be instances when non-standard parts are required. This can be overcome by establishing a process for managing exceptions, such as a formal request for deviation process. This process should be clearly communicated to all employees and should include guidelines for when exceptions are permitted and the steps that must be taken to approve them.

D. Solutions to overcome challenges

To overcome these challenges, it is important to establish clear procedures and guidelines for standardization, and to provide regular training and support to employees. Additionally, it is important to involve employees in the process of standardization and to clearly communicate the benefits of standardization to them. Finally, it is essential to establish a process for managing exceptions and non-standard parts, and to ensure that all employees are aware of this process.

V. Conclusion

A. Summary of key points

In this blog, we have explored the role of standardization in spare parts management, including the benefits it provides, the challenges it poses, and the solutions that can be employed to overcome them. We have also discussed the steps that can be taken to implement standardization in spare parts management.

B. Importance of standardization in spare parts management

Standardization is crucial in spare parts management as it helps to improve inventory control, reduce costs, increase efficiency, and improve customer satisfaction. Standardization makes it easier to identify, track, and manage spare parts, which helps to reduce the risk of stockouts and overstocking. Additionally, standardization makes it easier to ensure that the right parts are being used in the right equipment, which helps to prevent downtime and prolong the life of equipment.

C. Future outlook

The future outlook for standardization in spare parts management is positive, as more and more industries are recognizing the benefits that it provides. With the growth of Industry 4.0, the use of advanced technologies such as RFID, IoT and AI are expected to further improve inventory control and reduce waste. This will ultimately result in more efficient and cost-effective spare parts management. Additionally, more companies are expected to adopt standardization to meet the industry standards and regulations, making it a crucial part of the spare parts management process.