Leveraging Technology to Streamline Spare Parts Management

Leveraging Technology to Streamline Spare Parts Management

I. Introduction

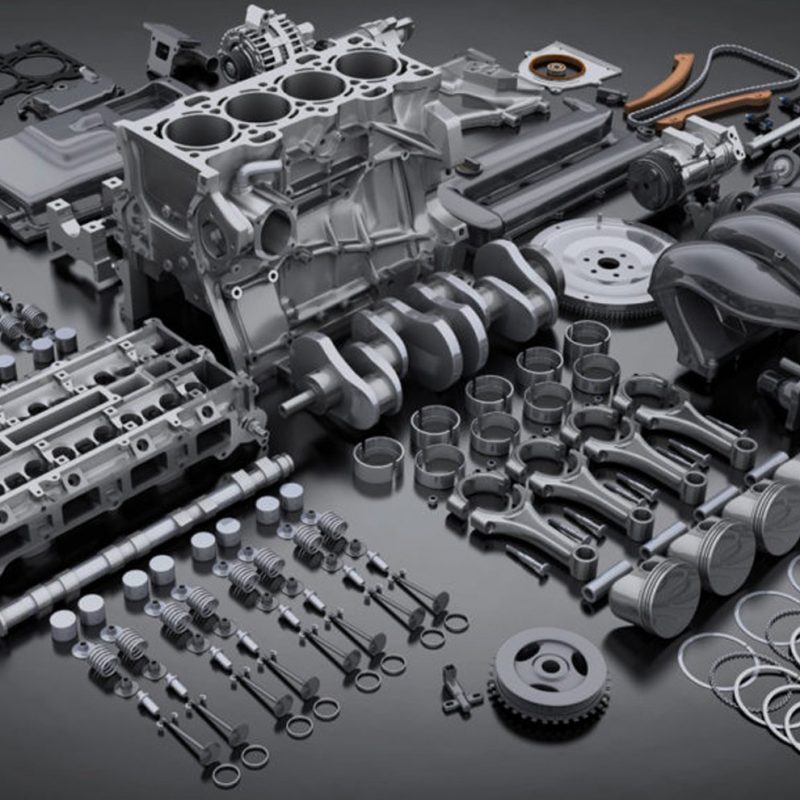

A. Spare parts management is a crucial aspect of manufacturing and logistics operations. It involves the tracking, ordering, and maintaining of spare parts and components that are needed to keep equipment and machines running smoothly. Without effective spare parts management, manufacturers and logistics companies can face costly downtime, production delays, and other operational challenges.

B. Despite its importance, managing spare parts can be a complex and time-consuming task. Some of the main challenges include:

- Keeping track of the large number of different parts and components that may be required

- Managing inventory levels to ensure that parts are available when needed without overstocking

- Forecasting demand for spare parts and determining the appropriate level of inventory to hold

- Managing relationships with suppliers and vendors to ensure timely delivery of parts

- Ensuring that the correct parts are ordered and received to avoid errors and delays

- These challenges can be further complicated by the fast-paced and ever-changing nature of manufacturing and logistics operations, making it difficult for companies to keep up with the latest trends and technologies.

II. The impact of technology on spare parts management

A. Technology has had a significant impact on the way spare parts are managed in manufacturing and logistics operations. There are a variety of technologies that can be used to improve spare parts management, including:

- Inventory management software: These software systems are designed to help companies track and manage their spare parts inventory levels. They can be used to automate the process of tracking inventory levels, reordering parts, and generating reports.

- Automated inventory replenishment systems: These systems use advanced algorithms to automatically determine when to order new parts based on current inventory levels and usage patterns. This helps to eliminate the need for manual monitoring and reordering and reduces the risk of stockouts.

- RFID and barcoding technology: RFID (Radio Frequency Identification) and barcoding technology can be used to automate the process of tracking spare parts as they move through the supply chain. This allows companies to quickly and easily locate parts and ensure that they are being used in the most efficient way possible.

B. The use of technology in spare parts management can provide a number of benefits, including:

- Increased efficiency and accuracy: Technology-based systems can automate many of the manual tasks associated with spare parts management, such as tracking inventory levels and reordering parts. This can help to reduce errors and improve the overall accuracy of spare parts management.

- Reduced lead times and costs: Automated inventory replenishment systems and RFID technology can help to reduce lead times by ensuring that parts are ordered and delivered in a timely manner. This can help to minimize downtime and reduce costs associated with stockouts.

- Improved forecasting and demand planning: Advanced inventory management software and RFID technology can provide real-time data on usage patterns, which can be used to improve forecasting and demand planning. This can help to ensure that the right parts are available at the right time, reducing the risk of stockouts and excess inventory.

III. Case studies and examples

A. There are many real-world examples of companies that have

successfully implemented technology-based spare parts management systems. For instance, a large aerospace manufacturer was able to reduce its inventory carrying costs by 30% by using automated inventory replenishment systems. Another company that operates heavy equipment was able to improve its inventory turnover by 25% by implementing RFID technology to track and manage spare parts. These are just a couple examples of how technology can significantly improve spare parts management.

B. Despite the many benefits that technology-based systems can provide, there are also several challenges that companies may encounter when implementing these systems. For example, one common challenge is the need to integrate new technology with existing systems and processes. This can be a complex and time-consuming task, requiring significant resources and expertise. Another challenge is to ensure that the right data is being collected and analyzed to make informed decisions. This requires a good understanding of the data and the ability to extract insights from it.

To overcome these challenges, companies may consider working with specialized vendors or consulting firms that have experience in implementing technology-based spare parts management systems. They can provide expertise and support in areas such as data analysis, system integration, and training. Additionally, companies should ensure that they have a clear understanding of their own operations and requirements before selecting a technology-based solution and make sure that it aligns with their goals and objectives.

IV. Best practices for implementing technology-based spare parts management

A. Implementing technology-based spare parts management systems can be a complex and time-consuming task. Here are some best practices to follow when implementing such systems:

- Start with a clear understanding of your business needs and objectives.

- Conduct a thorough assessment of your current spare parts management processes and systems to identify areas for improvement.

- Carefully evaluate different technology-based solutions to determine which one best fits your specific needs and requirements.

- Develop a detailed implementation plan that outlines the steps and timelines for implementing the new technology.

- Involve all relevant stakeholders in the implementation process to ensure buy-in and support.

- Test and evaluate the new technology before rolling it out to the entire organization.

- Provide training and support to ensure that all employees are able to effectively use the new technology.

- Continuously monitor and evaluate the performance of the new technology to identify any issues or areas for improvement.

B. One of the key components of technology-based spare parts management is data management and analysis. The ability to collect, store, and analyze data on spare parts usage, inventory levels, and other key metrics is critical to making informed decisions and optimizing operations. Therefore, it’s important to consider data management and analysis capabilities when evaluating different technology-based solutions. This includes the ability to easily extract insights and generate reports, as well as the ability to integrate with existing data systems and processes.

Additionally, companies should establish a data governance framework that outlines data ownership, access, and use policies to ensure data integrity and security. This will help to ensure that the data is accurate, reliable, and can be trusted for decision making.

V. Conclusion

A. In this blog post, we discussed the importance of spare parts management in manufacturing and logistics operations and the various challenges that companies face in managing spare parts. We also highlighted the impact of technology on spare parts management and the various technologies that can be used to improve the process, such as inventory management software, automated inventory replenishment systems, and RFID and barcoding technology. We also provided case studies and examples of companies that have successfully implemented technology-based spare parts management systems and the specific challenges and solutions that were encountered in these cases.

B. Leveraging technology to streamline spare parts management can provide a wide range of benefits such as increased efficiency, reduced lead times and costs, improved forecasting and demand planning and many more. It is a powerful tool that can help companies optimize their spare parts management operations, reduce costs, and improve overall performance.

C. If you’re looking to improve your spare parts management operations, we strongly encourage you to consider implementing technology-based systems. By following the best practices discussed in this blog post, you can ensure that your implementation is successful and that you are able to fully realize the benefits of these systems. Whether you’re looking to improve inventory management, reduce lead times, or improve forecasting and demand planning, technology-based spare parts management systems can help you achieve your goals and improve your bottom line.