5 Tips for Effectively Managing Spare Parts Inventory

5 Tips for Effectively Managing Spare Parts Inventory

Introduction:

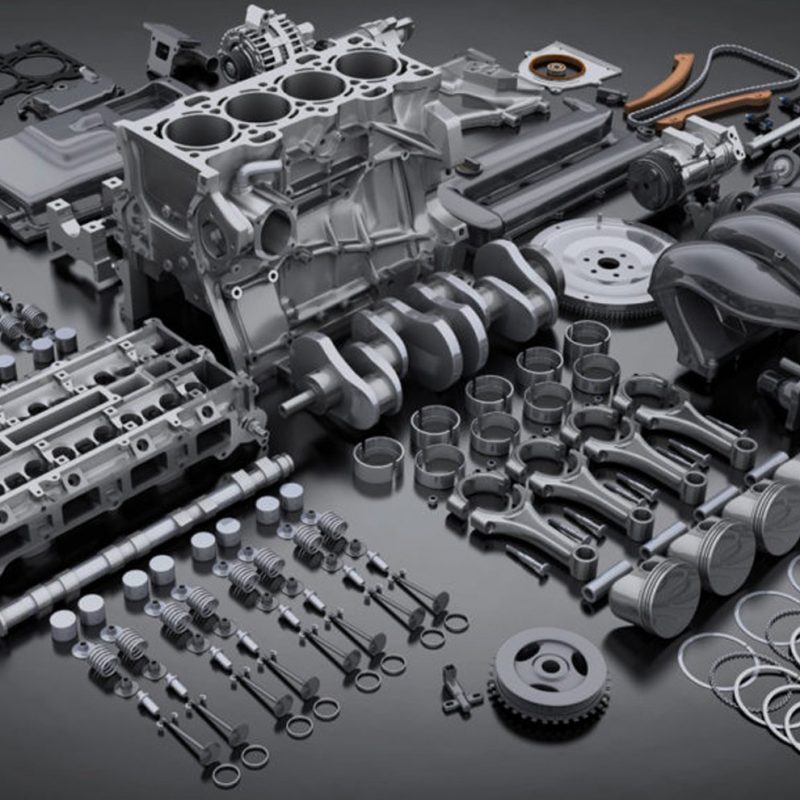

Effectively managing spare parts inventory is crucial for any business that relies on equipment or machinery to operate. Not only can it help to reduce costs and improve efficiency, but it can also ensure that the right parts are on hand when needed and that older parts are used before they expire or become obsolete. The purpose of this blog post is to provide 5 tips for effectively managing spare parts inventory.

Tip #1: Implement a FIFO (First In, First Out) system for managing spare parts.

One of the most effective ways to ensure that older parts are used before they expire or become obsolete is to implement a FIFO (First In, First Out) system for managing spare parts. With this system, the oldest parts are used first and the newest parts are used last. This can help to ensure that parts are used before they expire or become obsolete, reducing the risk of waste and the need to replace parts unnecessarily.

Tip #2: Utilize barcoding or RFID technology to improve inventory tracking.

Another effective way to improve the management of spare parts inventory is to utilize barcoding or RFID technology. These technologies can help to accurately track inventory levels and make it easier to identify and locate specific parts. This can help to reduce the risk of stockouts and ensure that the right parts are on hand when needed.

Tip #3: Regularly review and assess inventory levels to identify slow-moving or excess parts.

It is important to regularly review and assess inventory levels to identify slow-moving or excess parts. This can help to reduce costs and improve efficiency by reducing the amount of inventory that needs to be stored and managed. It also helps to identify any parts that are not being used or are no longer needed, which can be returned to the supplier or sold to reduce costs.

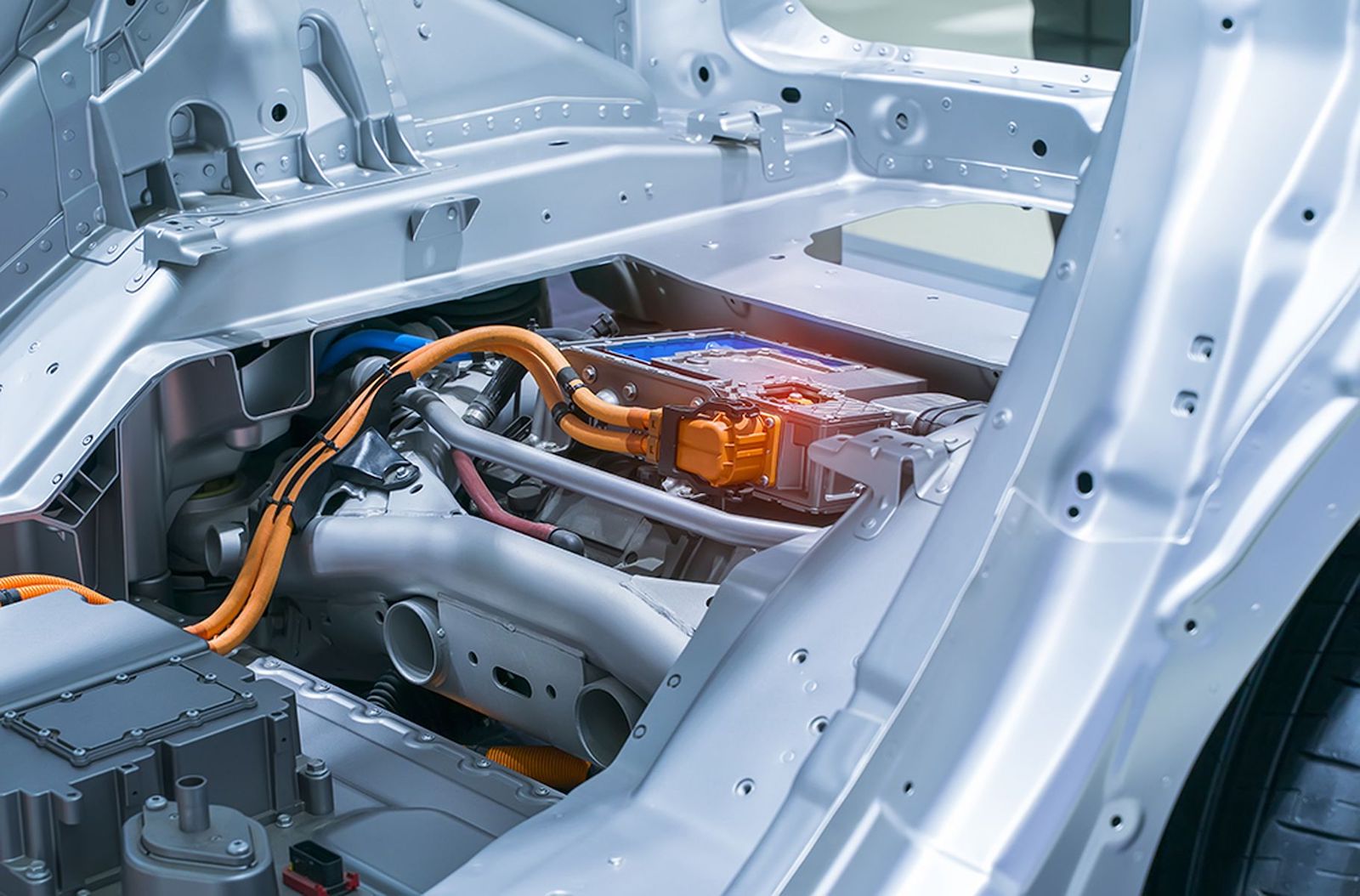

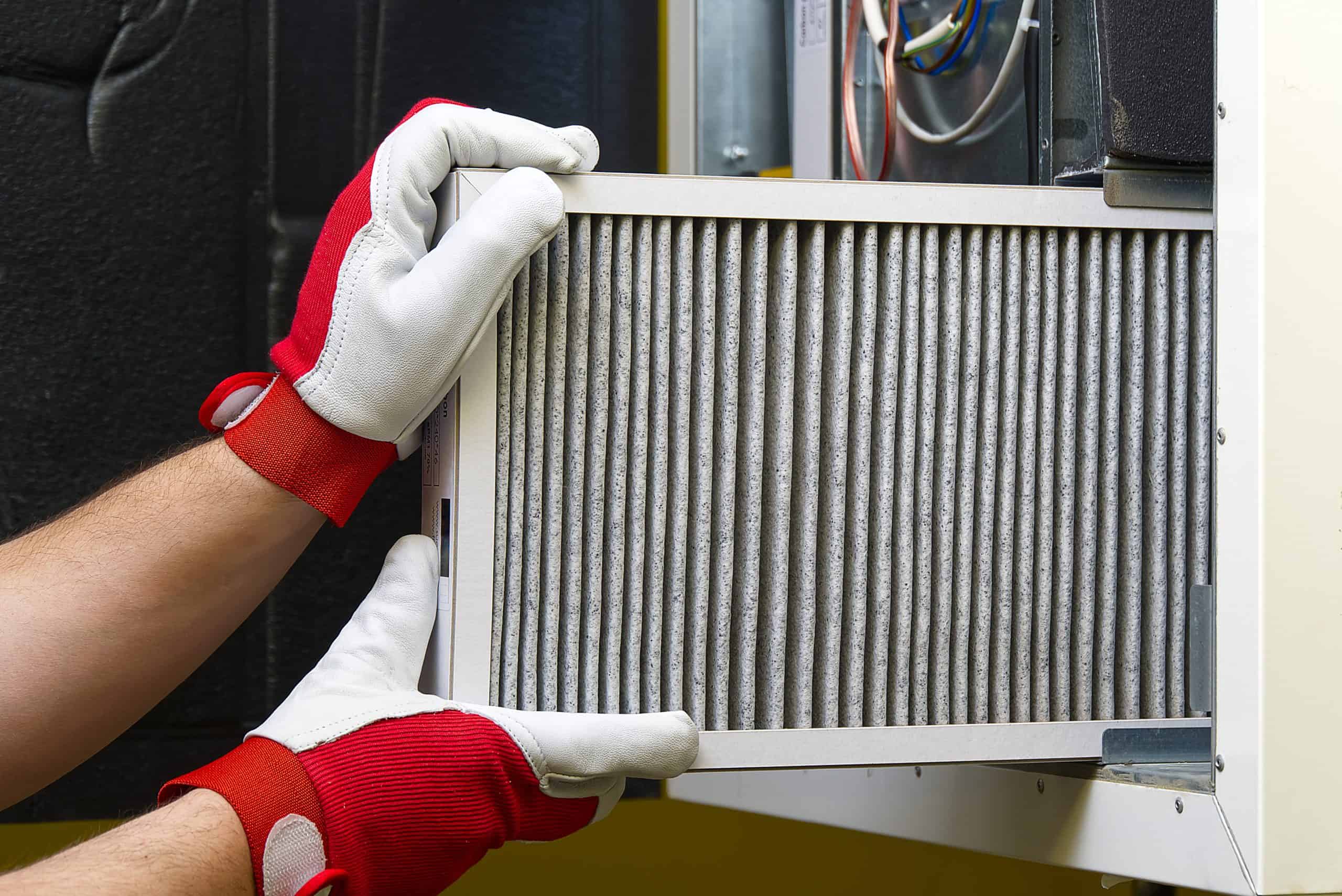

Tip #4: Establish a preventive maintenance program for equipment.

Establishing a preventive maintenance program for equipment can help to reduce the need for spare parts and prolong the life of equipment. Regularly maintaining and servicing equipment can help to identify and address any potential issues before they become major problems, reducing the need for spare parts and prolonging the life of equipment.

Tip #5: Collaborate with suppliers to manage inventory levels.

Collaborating with suppliers can also help to ensure that the right parts are on hand when needed and can help to reduce costs and improve efficiency. By working closely with suppliers, businesses can ensure that they are always well-stocked with the parts they need and can take advantage of any discounts or special deals that may be available.

Conclusion:

In conclusion, effectively managing spare parts inventory is crucial for any business that relies on equipment or machinery to operate. By implementing a FIFO system, utilizing barcoding or RFID technology, regularly reviewing and assessing inventory levels, establishing a preventive maintenance program, and collaborating with suppliers, businesses can reduce costs, improve efficiency, and ensure that the right parts are on hand when needed. Keep in mind that, effective spare parts management is a continuous process, it requires attention and adjustment over time.